RFID-Based Inventory Management

Managing inventory levels of such products as stickybacks, tapes, doctor blades, and other miscellaneous items can be labor-intensive and time-consuming. Even careful attention to stock levels can be suspect if requirements change quickly due to unforeseen events. Typical vendor-managed inventory or consignment programs can also fall short as they are dependent on periodic counts vs. real-time information.APR's SupplySentry website (above) can answer all of your questions about our SupplySentry Inventory Management System. Click here to learn more.

APR's roots in RFID-managed inventory tracking date back to 2004 and the company remains at the forefront of RFID technology testing due to nearly 15 years of software development. APR's new SUPPLYSENTRY system is the culmination of a decade and a half of software development expertise and marketplace testing.

The goal was to develop a solution that offered reliable real-time inventory management with a user-friendly user interface that reduced "stock-out risk", optimized inventory levels, and saved time. After continuous investments and improvements, APR's RFID-based SUPPLYSENTRY was launched. Today's SUPPLYSENTRY system is a proven solution for real-time inventory management delivering real supply chain value.

APR's SUPPLYSENTRY RFID-enabled Flexo Supply continuously monitors all of the supply items that you use on a daily basis such as stickybacks, tapes, doctor blades, end seals, photopolymer, safety supplies, and much more.

Today's flexo printer cannot afford to have stock-outs. The cost of shutting down a press for lack of the right end seal or changing the schedule because you do not have the right stickyback to mount a job is unacceptable.Johnna Hanson, American Packaging Corp.

This system utilizes the latest in RFID technology to automatically keep track of what you use and what you have on-hand. The system tracks inventory levels in real-time and utilizes Artificial Intelligence (AI) to anticipate your needs based on your usage history, and then calculates the quantities needed. APR alerts you when replenishment is needed, and all you need to do is approve the order. This allows you to focus on your business, and not on tracking your MRO supply levels.

More dependable than consignment inventory or traditional vendor-managed inventory programs.

Most systems today require a fair amount of human intervention to work efficiently to properly manage MRO or indirect material items. If not controlled properly, these systems may result in stock-outs or increased inventory amounts because the system is not operating on a real-time basis.

I have been so impressed with the team at All Printing Resources. They continue to bring new technologies to the table. I recently signed on with their Supply Sentry RFID Inventory Management system and wish I would have done it sooner. Their team came in and installed the shelving and the unit in 2 days and now I have worry-free and accurate live inventory of our production supplies. A tremendous tool from a tremendous team!!

Thanks, APR!!!Bob Burdick - Print Manager, Portco Packaging

A more real-time solution offers the ability to rapidly determine any changes in usage patterns and set up replenishment rules based more on just-in-time criteria, reducing costs. RFID is an excellent real-time business tool that helps better manage supply chains, increase profits, and decrease costs by improving visibility (and confidence) into your inventory management system to enable overall inventory levels, labor costs and safety stocks to be reduced.

View a video highlighting the features of the SUPPLYSENTRY.

The video shows how the system can help you reduce risk, lower working capital for excess inventory, optimize freight costs, and simplify your inventory management of many critical materials. Click the image below to view the video.

Let SUPPLYSENTRY help you guard your asset investments with RFID technology

- SUPPLYSENTRY can be set up with items having pre-determined minimum order quantities to generate automatic inventory replenishments or to generate an automatic e-mail to alert someone as to the need to order material.

- SUPPLYSENTRY is designed to make managing inventory simple, efficient, and more accurate than traditional methods.

- SUPPLYSENTRY is customizable to fit your strategic requirements, and can deliver measurable returns on your investment.

- SUPPLYSENTRY can also provide an integrated and modular RFID portal system, designed to provide the reliability, flexibility, and scalability needed for a variety of supply chain/inventory management applications.

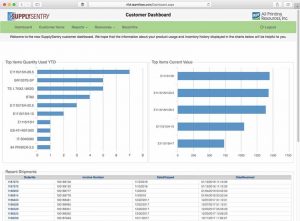

Web-based user interface

SupplySentry's web-based interface allows the customer to see at a glance what they currently have in stock. They can see what items they stock, the quantity of each item on hand, the quantity in transit, and the suggested amount needed to replenish their supply.The SupplySentry website also allows the customer to make adjustments to their inventory levels as their needs change. They can set the maximum quantity, the minimum quantity, and the re-order point for each item.

Customized Features Make SUPPLYSENTRY Even Better!

For large items that are too big to fit into a cabinet, like cases of photopolymer plates or large rolls of mounting materials, our rack monitoring system can track inventory stored on shelving. And, for those items that are too small to hold an RFID tag, or ship in cases with quantities so large that we can't tag each individual item, we can integrate scales into the cabinets to track usage of these items by weight. And if security is needed, we now can provide locked storage that can only be accessed with a fingerprint scan.