Customer: Prairie State Group, a full-service printer of unique packaging products, such as narrow-web flexible packaging, as well as pressure-sensitive labels.

Situation: With significant funds being spent outsourcing digital platemaking, this printer needed to go from conventional "analog" platemaking to a more accurate, more consistent, higher quality and flexible in-house digital process. Solution: After an extensive fact-finding and interviewing process, Prairie State Group chooses All Printing Resources to help them transition, implement and support a new digital platemaking process. Bottom Line: All Printing Resources delivers a comprehensive digital solution that helps Prairie State Group eliminate outsourced digital platemaking expenses, improves internal processes, maximizes efficiency and delivers better results for their customers.The Story

"The market has become more demanding when it comes to platemaking," says Dan Doherty, Executive VP of Operations and co-owner of Prairie State Group. "Many of our clients were anticipating and demanding a higher quality digital process that could do much more, such as print complex graphics more precisely. Going digital eventually became a matter of necessity, both economically and, more importantly, to satisfy our valued clients."

This was especially true for their Prairie State Impressions division, which focused primarily on delivering flexible packaging solutions for consumer goods products, many in the highly-competitive food industry. With flexible packaging needs in critical consumer niches such as meat and cheese, canned food, nutritional bars, ice cream novelties and much more, the customer-focused printer needed to go digital quickly and seamlessly.

APR Provides a "Right Out of the Box" Solution

With 70% of their business hinging on flexible packaging for consumer food markets, Prairie State Group could not afford interruptions in workflow and processes. Naturally, this was the biggest fear-that the transition from conventional film to digital platemaking would "gum up the works," costing the printer valuable time and expense, as well as the potential for customer service issues.

"What was most critical for us in choosing a digital partner was the ability and resources to get us up and running as quickly as possible, right out of the box," says Doherty. "I'll be honest... we needed our hands held. We'd been doing business with conventional platemaking for over 15 years. So we were afraid that uprooting our operation and redoing the process could impact workflow and cause production problems. But, when we made the decision to go with APR, that fear was very quickly dispelled."

Executive VP of Operations & co-owner, Prairie State Group

The Digital Platemaking Solution

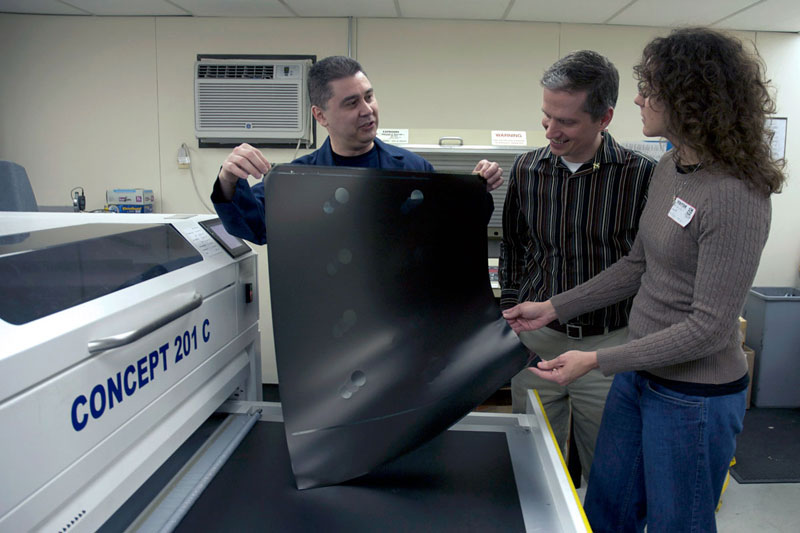

APR provided Prairie State Group with a customized cutting edge solution to help them produce high-quality digital photopolymer plates. Some of the features and benefits of this solution included:

- Mekrom (Glunz & Jensen) plate processing equipment: Combines in-line washout technology with the latest technology in high speed drying for quality photopolymer plates in approximately 75 minutes

- Air quality control: The Mekrom in-line combined with today's new solvents and the Island Clean Air filter significantly reduces VOC's and odors in the plate making process

- Solvent handling program: APR makes the handling of solvents easy to manage, helping to create a fixed cost while assuring a high quality plate

- Flint plates: Proven to deliver better ink mileage and densities than thermal plates, Flint plates lower overall ink cost and allow for higher press speeds with better consistency from plate to plate

- Laser Plate Setter: Twice as fast as a 15 optic machine with 48 independent thermal laser diodes in a redundant array fiber bundle-no loss in quality and less downtime if a laser fails

- Fast equipment service: Local APR technicians provide service on Mekrom equipment and multiple tech service reps in the Chicagoland area ensures fast support and maximum up time

The Benefits

"Since we pulled the trigger on doing this over a year ago, our investment with APR has paid for itself very rapidly," says Doherty. "In fact, it is the fastest ROI that I've had with an equipment investment in over ten years."

Other benefits from the partnership with APR that Doherty cites include:

- Increased ability to provide a faster turnaround on plates

- A higher quality of press time

- Greater customer satisfaction

- Less downtime on the presses

- Better proof-to-press matching

As the man "in the trenches" for Prairie State Group, Charles Strezo, Pre-press Manager, also sees some significant benefits day in and day out: "We can now give our customers something much cleaner and crisper, plus the proofing software shows them-with a very high degree of accuracy-exactly what they'll be getting. We can hit colors and complicated graphics more precisely, and have much greater control over the process."

"The keys to getting Prairie State Group up and running quickly were managing expectations and planning a detailed route from where they were to where they wanted to be," says Richard Black, Director of Digital Solutions at APR. "And before we got started, we tackled each concern one at a time, making sure we dispelled any fears or misinformation about going digital. Once we had a clear vision and path, things moved along very quickly."

Pre-press manager

Prairie State Group