With new demands on flexo plates such as Full HD Flexo, 175+ LPI, and high speed presses, optimized platemaking conditions are more important than ever. At the heart of the platemaking process is a light source - UVA light to be specific - which is the foundation for producing high quality plates time after time. In this blog post, we'll expose the importance of monitoring your UVA lamps, and provide tips to ensure consistent platemaking success.

Bank Light Systems: Fluorescent UVA Bulbs

By far the most common method of exposing flexo plates is the use of a bank light system. That is, an exposure frame with a set of closely-aligned UVA bulbs. These systems provide an overall wash of UVA light to the exposure bed beneath the bank of lights when in operation. A tried and true design, but precautions must be taken to ensure consistent results:1. Measure Light Output Regularly

- Discuss the acceptable UVA output limits for your plate and process with your supplier.

- You will need a specialized tool called an UVA meter to perform the measurement. UVA meters are available for purchase through APR, and training is also available.

2. Changing Bulbs

- If one or more bulbs go out, the entire set needs to be replaced- at the same time. There's no savings in making inconsistent plates with a mix of new and old exposure bulbs.

- Replacement bulbs are available through a variety of manufacturers. Just be sure the power specifications and size match the equipment, and the output wavelength matches your application.

- Check to see if the bulbs have a reflector (the reflector will usually have a white appearance on one half of the bulb). If so, make sure the reflector side is facing the top of the machine, allowing the non-reflector side to face the exposure bed.

- Install the bulbs, alternating the manufacturer's logo from one side to the other as you work your way through the unit. This will ensure the most even light distribution possible.

- Always wear clean cotton gloves to protect the new bulbs during installation. The oil from your skin can damage the delicate glass exterior.

3. Keep Your Equipment Clean:

- Dust the bulbs regularly with a clean, dry, soft cloth.

- Check the exposure bed and cooling fans for any dust buildup.

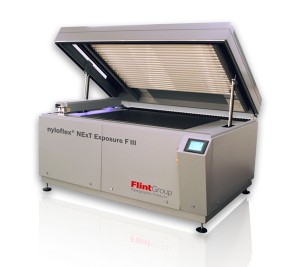

LED Light Systems: Inline and Offline

While there is little to no degradation of light output with LED light sources, there are fewer steps to ensure consistent plate quality. Let's touch on the same points as above so the difference is clear:1. Measure Light Output:

- The latest LED exposure technologies feature built-in light output measurement to ensure the proper dosage of UVA light is being delivered. This means manual measurement is not needed.

2. Changing Diodes:

- Diode changes are rarely needed, as most LED manufacturers claim a life of 20,000 hours or more.

- If a diode goes out or becomes defective, the unit can usually compensate by increasing the light output from the working diodes until the defective diode can be replaced.

3. Keep Your Equipment Clean:

- Follow the manufacturer's instructions for cleaning dust from the LED lamp.

I have question? In a light finishing unit. Is UVA the detact or is UVC