The Resins Remain Behind

We have hand cleaned anilox rolls using stainless steel brushes and primarily caustic chemicals, ultrasonic, and media blasting [which can limits some line counts on anilox rolls based on the particulate size of the media]. Most recently we have seen high-pressure solution wash systems that use detergents, chemicals, and water. The one thing that each of these methods have in common is that they ONLY break down ink pigment from the surface and cells of the anilox roll. But is this really good enough?

Solvent-based inks are made up of primarily of three components. The solvent acts as a carrier to get the pigment from the ink bucket to the substrate. The pigment gives the ink color. The resin offers performance characteristics such as waxes, the ability to stand up to light and not fade, and scuff-resistant properties. Water-based inks are formulated using four primary components, Water acts as the carrier, pigment is the colorant, the amines make the resin soluble, and resins offer up the performance characteristics as mentioned before. Which takes us back to the question we asked before; each of these methods break down the ink pigment from the surface in the cells of the roll but aren't the resins leaving things behind in the anilox cells? The answer is “yes”. That's why even after an anilox roll is clean you often notice the finish being different; most common—more glossy and darker than its original finish. The roll may have gone from a matte finish to more of a glossy finish because of the remaining waxes within the resin left behind.

Pump up the [BCM] Volume!

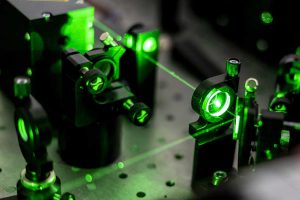

An ALC (anilox laser cleaner) uses light to enter the cells and vaporizes ALL the remaining components of the ink including the resins. There is no LPI limitation beyond the capability of the ALC, because you cannot escape the light. The laser beam is strong enough to vaporize any ink, varnish, coating, or adhesive without touching the ceramic or chrome coating of your anilox rolls. All of the used anilox rolls in your current inventory have some degree of remaining resins left behind which takes away the ability to carry the full volume (bcm) potential. When calculating an ROI you could then argue that these systems are not merely cleaning better; you are refurbishing your existing inventory to some degree. Speaking of ROI, laser cleaning technology does not require any chemicals, media i.e. sodium bicarbonate or polymer beads, water, detergents, or waste disposal of any kind.

Low energy and still eliminate caustic chemicals and waste?

Minimizing the use of these chemical cleaning agents is certainly a step in the right direction to reduce generated waste. Some select lasers used in these state-of-the-art cleaning systems are considered to be Class 4, however units with lasers completely contained with interlocks can result in the unit being rated as a Class 1 device by the FDA. The definition of Class 1 is equipment inherently safe with no possible ability of eye damage.

Final Thought

I personally believe ALCs will take over anilox cleaning in the long term future. Admittedly some manufacturers of ALCs are still working through some growing pains, but in large the technology is solid and continues to be perfected. The price of these systems is higher than competitive anilox cleaning technologies but the ROI is often short when considering longer usage of the anilox and eliminating cleaning consumables and waste. This technology is not just a fad, but a long term solution to anilox care.

If you want to learn more about this subject, please feel free to reach out to us by calling 1-800-445-4017, or by e-mail at [email protected].

All Printing Resources has formed our Technical Solutions Group (TSG) to encompass our full range of expertise in all critical areas of the flexo process. This team is made up of industry professionals dedicated to being up-to-date on new technologies along with best practices. They are armed with the latest in diagnostic tools and are experienced in problem-solving that can achieve sustainable results. The TSG has walked in your shoes, and have felt your pain.