Clarifying the Facts for G7® or NNC

G7® (also called Near Neutral Calibration, NNC) is not a new term and I am sure many already have at least a basic understanding of what it is, but in my discussions with individuals and companies I still encounter some confusion on the true meaning and application for G7®. To simplify it, G7® is a methodology for gray balancing a print system to a known calibration target. The primary benefit being that we can remove some of the inherit color cast in various print systems and then point them to a common calibration target to improve the color match between print systems. I am highlighting the 5 top misconceptions I encounter when discussing G7®/Near Neutral Calibration.

MYTH 1:

G7® is a process that applies to Offset Printing.

FACT:

G7® is a gray balancing process that applies to any print system. A print system includes proofers, digital presses, flexo presses, offset presses, gravure presses, screen printing, etc. A G7 Master may have multiple print systems of a common type (such as flexo paper and flexo film printing) and/or may span over multiple print disciplines (such as digital, offset and flexo).

MYTH 2:

G7® is color management for the press room.

FACT:

G7® has an impact on color appearance, but it is really a calibration process. Rather then only compensating for dot gain or loss in a system G7® also compensates for the color balance of a system (CMYK impurities and ink trap) via curves.

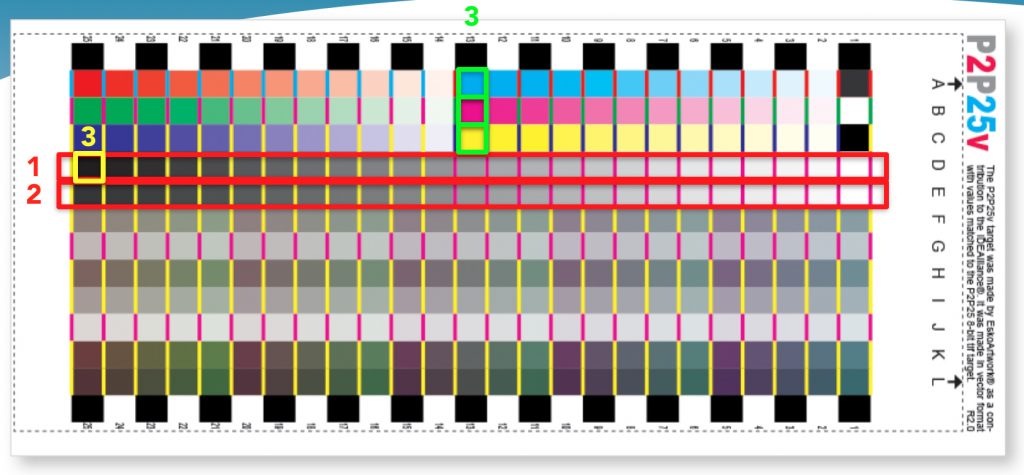

![Image to show different print systems aligning to a common neutral appearance. Image to show different print systems aligning to a common [G7®] neutral appearance.](https://www.teamflexo.com/wp-content/uploads/2017/04/G7_sm-1024x768.jpg)

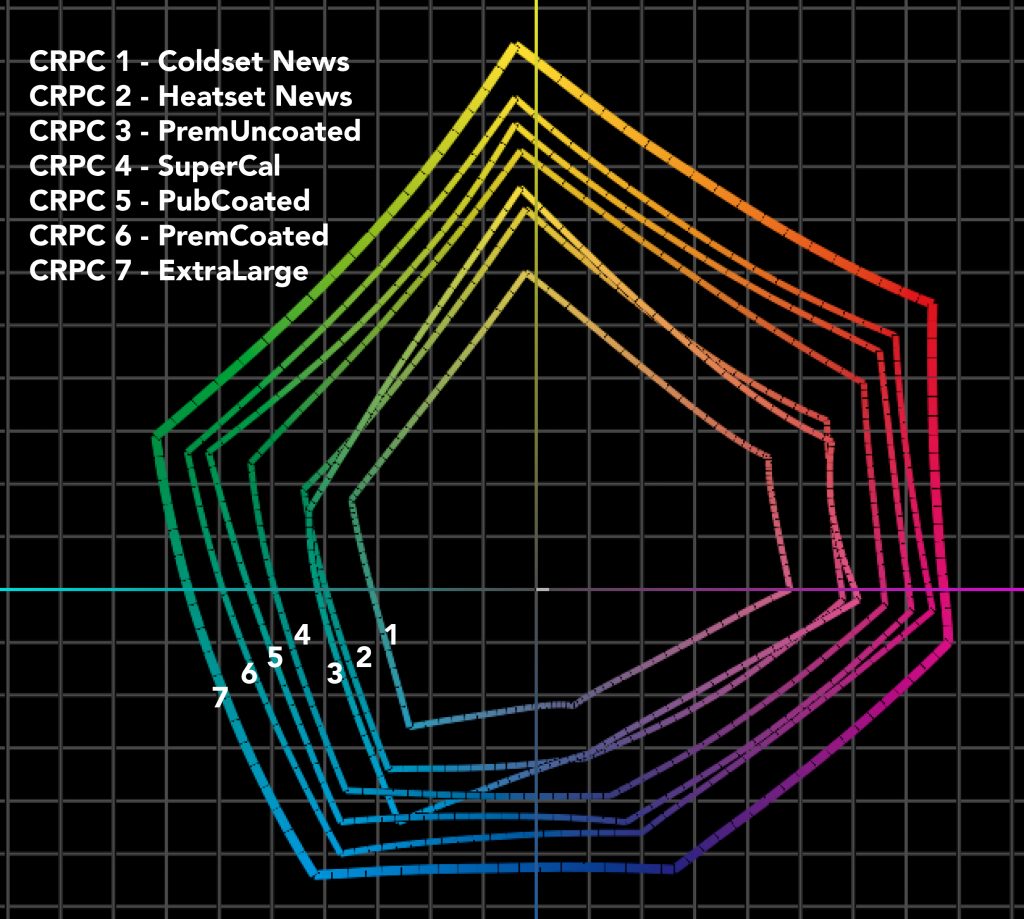

Bringing different print systems (or print conditions) to share a common neutral appearance.

MYTH 3:

G7® only applies for printers using ISO targeted inks & substrates.

FACT:

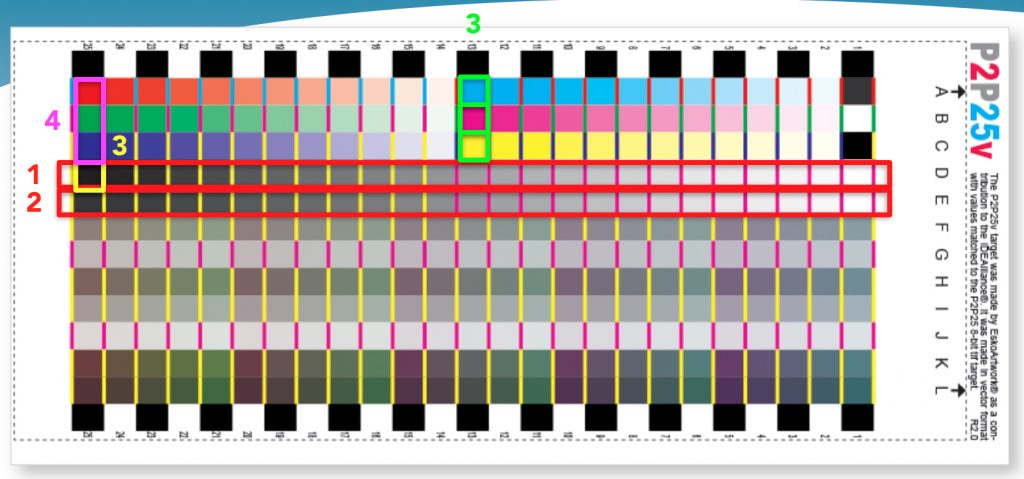

There are 3 levels for G7® Qualification:- G7® Grayscale

- G7® Targeted

- G7® Colorspace

LEVEL 1: G7® Grayscale - The Grayscale compliance level is available to printers who are not able to hit the CMYK solid CIEL*a*b* values or substrate specs within tolerance, but are still able to gray balance their print system. The expectation is a close match to the target neutral print density curve (NPDC) for Black and CMY scales. A close match to the target gray balance for CMY scale. CMYK solids should target as close to a specification as possible, but may be run as "native".

LEVEL 2: G7® Targeted - The expectation for Targeted compliance is a close match to the target neutral print density curve (NPDC) for Black and CMY scales. A close match to the target gray balance for CMY scale. CMYK solids should match target within ΔE tolerance. RGB overprints must also match targets within ΔE tolerance.

LEVEL 3: G7® Colorspace - The expectation for Colorspace compliance is a close match to the target neutral print density curve (NPDC) for Black and CMY scales. A close match to the target gray balance for CMY scale. CMYK solids should match target within ΔE tolerance. RGB overprints must also match targets within ΔE tolerance. All other points in a G7®-based color space should also be a close match.

MYTH 4:

G7® is the same as GRACoL 7.

FACT:

- G7® is a methodology for gray balancing

- GRACoL is a specification/guideline for implementing a print standard - currently based on 7 reference print conditions

- Both reference ISO standards

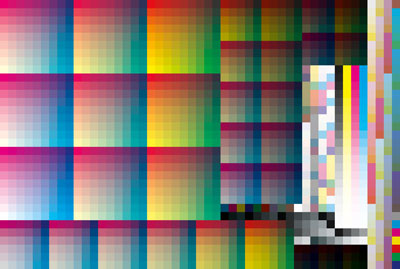

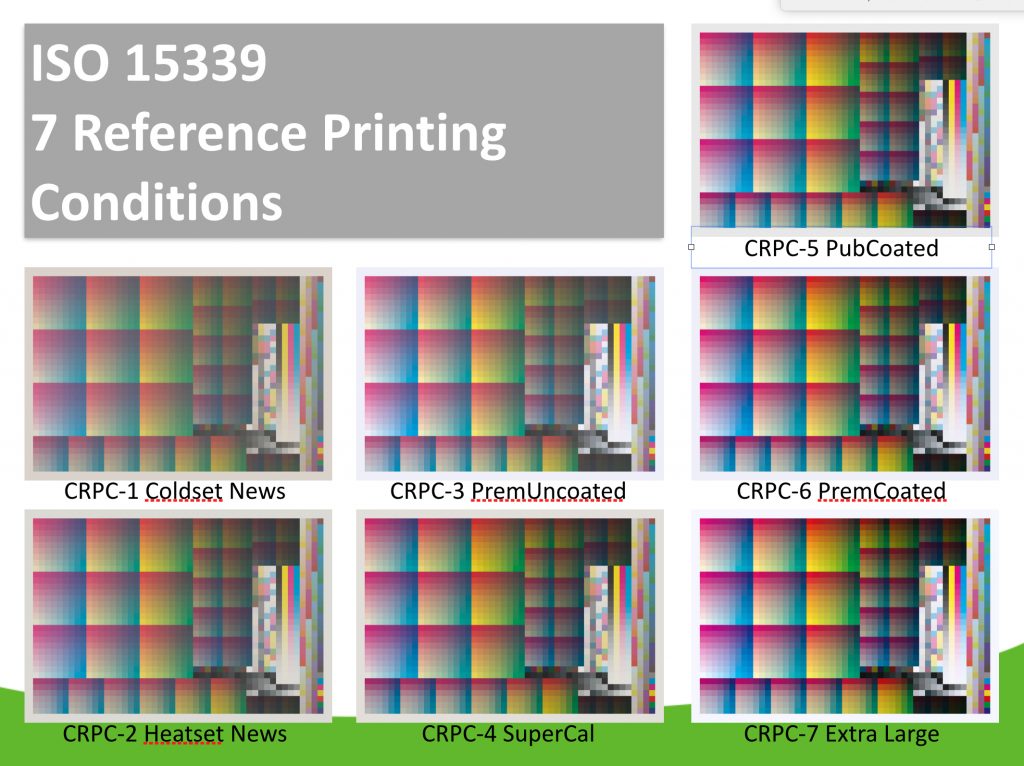

So, the G7® methodology can be applied to the GRACoL specification (or other desired specifications), both referencing a common ISO standard. GRACoL 2006 and 2013 correlate to the current ISO RPC 6 (see images below).

In 2013 seven updated Characterized Reference Print Conditions (CRPC) were released – CGATS 21 or ISO 15339. All measurements in these datasets are specified in M1.

![Chart comparing 7 new [2013] ISO Reference Printing Conditions to US and European References Chart comparing 7 new [2013] ISO Reference Printing Conditions to US and European References](https://www.teamflexo.com/wp-content/uploads/2017/04/ISO_CRPCPrintConditions2_sm-1024x766.jpg)

MYTH 5:

A G7® Master qualification is not really applicable for my facility.

FACT:

To qualify as a G7 Master printer you must calibrate and verify your print system(s) and submit those press run(s) (via a G7 Expert) to IDEAlliance. However, if you do not aspire to be qualified as a G7 Master printer, you can still benefit greatly by applying the methodology to your process(es). This can be especially beneficial to printers with multiple print systems that do not print similarly.

can we publish this in portughese with the credits?