Sometimes things get so old they are actually new again.

I love when my kids hear me say something or hear music they thought was new and cool (or as they say, "Kewl") only to find out it is really old!

The same can be said for some technologies. Take Graphic Arts film from example. Yes, some people still use film. And why not, it is a great storage device! Can you image how many GB’s it would take to define the text and graphics on single piece of 16x20 film negative imaged at 2400 dpi? Also, if you look at flexo plate technology, it has taken our industry 10+ years to realize that a Flat-top dot has significant print benefits, yet that same Flat-top dot has always been present in a film-to-plate or analog workflow.

The main problem with film is that it is becoming harder and harder to find. Matter of fact, a major film manufacturer has already stated they will discontinue film production this November! Not to mention film requires some pretty difficult chemistries that are no fun to handle or work with.

Several manufacturers have tried to develop film alternatives, such as using an inkjet plotter to print black ink on a mylar substrate to create film. They are several of these products on the market. In our testing, we could not find one that could reliably create film sufficient to make a flexo plate. The problem being the way an inkjet device creates an image. Imagine if I gave you a can of spray paint and ask you to create a 2” x 2” circle. Not matter how hard you tried there would always be a soft edge created by the overspray. If you viewed this circle from far enough away it would look very sharp but the closer you get to the circle the more of the soft edge or overspray you would see. The same goes for inkjet dots.

With flexo plates relatively long exposure time 8-12 minutes, the light from the exposure starts to burn through this soft edge or fringe creating inconsistent results on the final plate.

We have found a different technology for creating film. This technology uses a thermal imaging head to activate a specially-coated mylar material. When the thermal head activates the coating, it turns black. The result is a mylar material with solid black areas and clear (non-image areas) that looks and feels just like graphic arts film! The technology is completely chemical free.

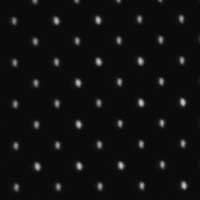

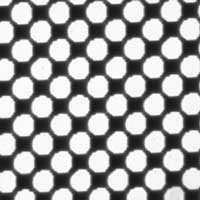

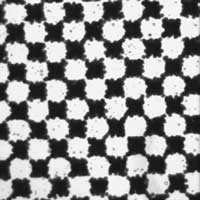

The thermal imaged film image compared to inkjet film is sharp and clear.

Comparing Thermal and Inkjet Film Imaging Quality

| 3% Dot | 50% Dot | Line | 6pt Reverse Type | |

|---|---|---|---|---|

Thermal Film |

|

|

|

|

Inkjet Film |

|

|

|

|

The technology is basically a fax machine that produces film!

All Printing Resources carries the EXILE line of thermal imagesetters, which offers a variety of sizes for nearly any application.

Thermal Imagesetter Pros:

- Excellent density, crisp edges – suitable for many applications.

- Durable film can be stored for 20+ years without degrading.

- Fast, chemical free film output. No processing or darkroom required.

- 1200 x 1200 dpi resolution is suitable for fine line work and screen rulings up to 120 LPI.

- Small device footprint, no extra processing equipment.

Thermal Imagesetter Cons:

- Not suitable for screen rulings over 120 LPI.

- Thermal print head is a consumable, but replacement can be covered with film purchase agreement.

So if you are looking at your imagesetter with your fingers crossed, as its on its last leg, or better yet don’t look at your imagesetter because you are afraid you will jinx it. Just contact your APR Technical Rep to discuss the Exile product line and see a sample of thermal film. It might be just the ‘good ‘ol technology’ you need. 'Kewl'