In my brief 12-year Flexo career (yes, I started in the dark side of printing — Litho! 😉 ), I have never seen a technology have such a dramatic impact on Flexo print quality as Flat; Top Dot plates.

Way back in 2010, I co-chaired the FTA Fall Conference in Louisville, KY along with Chair - Cayleigh Nichols (now Cayleigh Anderson) with the theme 'A FIRST rate idea'. The cornerstone of the conference was 'The Great Plate Debate'. We received special commercialism permission from the FTA to allow plate manufacturers to have their technical personnel explain their plate technology, kind of like bringing their sales product sheet to life. This was at a time when digital platemaking was becoming commonplace and Flat Top Dot (FTD) digital plates were just making inroads.

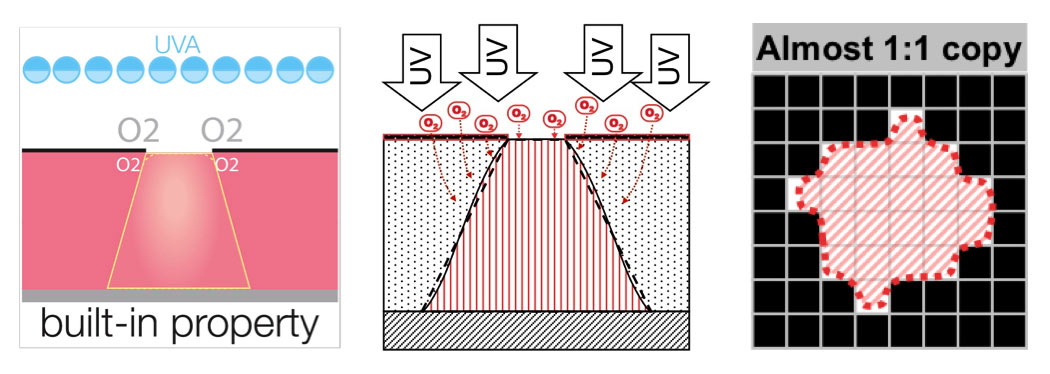

At the debate, Timothy Gotsick of MacDermid took a major stance stating that MacDermid was 'all-in' with Flat Top Dot plate technology because of all of the benefits: improved ink transfer, press stability, tonal range, highlight reproduction, higher lpi, the ability to use enhanced screening. All of which have now been proven to be true! ...I only wish I would have asked Timothy for a stock recommendation back then 😉

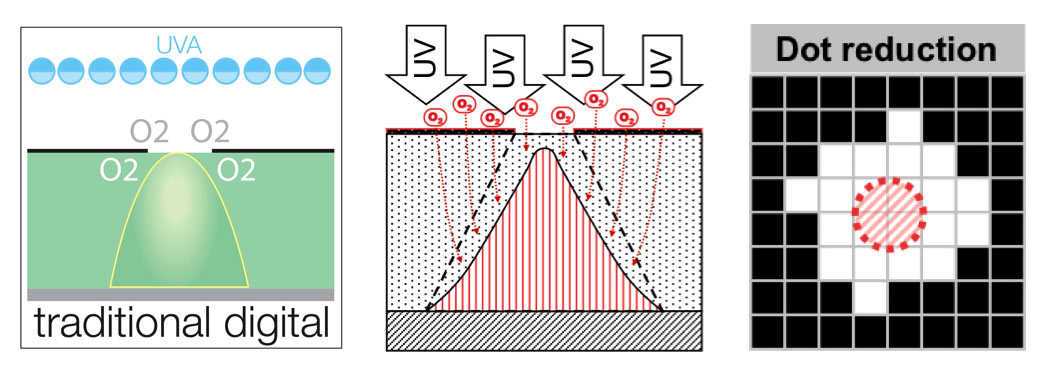

Until recently, it was somewhat difficult or at the very least cumbersome to make a Digital Flat Top Dot plate. In the last couple of years, this has changed with the advent of In-the-Plate (ITP) technology. Today every major plate manufacturer has developed and offers a plate that produces FTD plates right out of the box. The process to make a FTD plate is now the same as your current digital platemaking process. Back expose, image, face expose, process, post expose & de-tack.

You no longer need special exposure devices or lamination process, simply purchase the plates and go! You will need to review your current curves as the new FTD plates do not require a Bump curve because they don't sharpen during processing like traditional digital plates. If you are using extremely high line screen 200lpi + you may need a slight bump curve but even then it is very small, for example, .5 - 1.5%.

We have seen amazing print results using FTD plates and press operators love the extra impression latitude the plates offer. If you haven't tried FTD plates you need too! Regardless of the type of work you produce a FTD plate will likely show improvements and in many cases show vast improvements.

APR's Technical Solution Group (TSG) is currently working on a project to determine if we still need all of the different types of mounting tapes with increased press latitude of FTD plates? They have completed Part one of the study and they are working on Part two. More information can be found at: www.teamflexo.com/articles/what-is-the-best-tape-for-flat-top-plates-p1/

Click here for more information on APR's Flat Top Dot plate options. www.teamflexo.com/products/macdermid-lux-itp-plates/

I have always wondered about dot structure and its relationship to offset and litho printing. Can anyone advise on the varnish (Gloss and Matte) that you can lay-this-down with such accuracy as the ink. I was looking at a litho printed bag the other day from Trader Joes and the gloss varnish/UV was about 1.8″ outside the borders of the image.