Inkjet Digital Printing for Labels Can be Different...

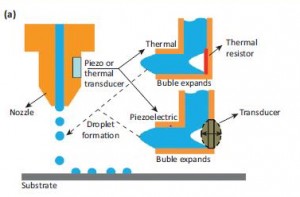

All inkjet technology is somewhat similar, a droplet of ink being ejected from a print nozzle, but how this is accomplished varies greatly depending on the vendors technology.

Some of the early inkjet technologies we based on Continuous Flow Inkjet.

- Ink was continually pumped from a reservoir through the nozzle

- Ink droplets were subjected to an electronic charge

- Image droplets were deflected to the receptor material by electronic deflection plates

- Non image droplets were not deflected and became waste

Most of the current inkjet products are based on Piezo Drop-On-Demand (DOD) technology.

Within this technology there are two types: Thermal or Piezo Electric. The difference is how the ink droplet is forced out of the ink chamber. Thermal technology creates heat that expands the chamber, pushing the ink droplet out. Piezo Electric sends an electrical signal to the ink chamber which forces the ink droplet out.

In the past 10 years ink droplet size measured in Picoliter have gone from 10 picoliter to 3.5 to new technology using 1.5. For reference, a Picoliter is 1/trillionth of a liter 0.000000000001/liter.

Two common ink types used in digital printing for labels are: Water based and U.V. based inks. Water based inks can use incredibly small picoliter droplets that dry on contact effectively forming to the surface of the substrate. Whereas common UV inkjet technology using larger picoliter droplets hit the surface of the substrate and then are quickly cured via a UV light creating a slightly raised surface.

There advantages and disadvantages to both ink types.

Water based inks

Pros- Quick drying via air

- Small Picoliter droplets (1.5 - 3.5)

- High print resolutions (1600+ dpi)

- Looks like Flexo ink on substrate

- Requires ink receptive substrate

U.V based inks

Pros- Ability to adhere to many substrates

- White ink possible

- Larger Picoliter droplets (3-5+)

- Low resolution (300-600 dpi)

- Slightly raised print surface

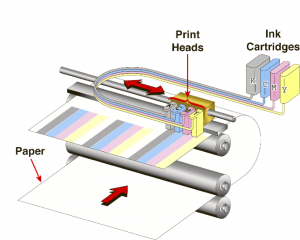

The major advancement in the last few year as it relates to digital printing using inkjet technology is the head design. Traditional inkjet printers use a carriage system to move the print head back and forth spraying ink onto a stationary substrate.

Today’s digital inkjet print technology uses linear print heads. These print heads range in print width and can be ganged to together to create wider print swaths. These print heads are stationary and substrate moves underneath them. This is know as Single Pass printing. The stationary print head allows for high print speeds.

Two major players in the single pass inkjet print head technology are Memjet and Xaar.

Memjet architecture MEMS, or microelectric mechanical systems, is a nanoscale technology based on Drop-on-Demand thermal inkjet. Memjet licenses their technology to several integrators.

Specification

Ink Nozzles 70,400

Print width 8.77”

Resolution 1600 x1375 dpi

Ink type Water base

OEM prints speeds 275 ft/min

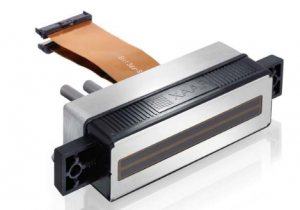

Xaar is a piezoelectric drop-on-demand design that also uses a continuous flow type of inking system. Xaar licenses their technology to several integrators.

Specification

Ink Nozzles 1,000

Print width 70.5 mm (2.77”)

Resolution 360 npi (effective 1000dpi)

Ink type UV, Solvent

OEM prints speeds up to 157 ft/min

There are many presses on the market utilizing these two inkjet head manufactures as well as others such as Screen and Fujifilm. A new product entering the digital printing for label market is coined Hybrid Flexo. Where a digital print unit is added to an existing Flexo press creating a Hybrid digital flexo press. More information on this product to follow in a future post....