Are you ready for more fun with regulatory compliance? …Actually this part is pretty cool and a little more fun. In the first part of this discussion I talked about where labeling regulations are derived, the types of package/labeling elements that are regulated and how prepress providers can use software to aide in meeting many government labeling requirements. Remember, my focus in this article is regulations related more specifically to the graphics, for things like font specifications, barcodes, ingredients panels and nutritional panels. These are especially important considerations to Flexo prepress and packaging prepress. As an example, I mentioned the recent Nutritional Panel change that introduced the most significant change to this type of information in many years.

If you did not see the first part of this article, you should click this link to learn more about the FDA Proposed Nutrition Fact Changes. I also talked about the first layer of defense everyone should use when opening an art file – preflighting. Some solutions are very intuitive and act as a guide allowing the user to move through the file and correct elements as needed. But preflight is really only the tip of the iceberg when it comes to most graphic related regulations. I now would like to discuss using dynamic content to build things like intelligent barcodes and nutritional panels.

How Smart is your Barcode Builder?

Barcode generating programs have been around forever and are essential to successfully creating a barcode with the correct bars and spaces, size, magnification, bar width reduction and height. There are a variety of applications you can purchase and use to build a barcode, which can then be placed into Adobe Illustrator®. Since you are creating a [raster-based] image file a change to that barcode requires going back to the barcode application to generate a new code. The bad barcode must then be deleted from the Illustrator® file and the corrected code placed and repositioned where needed within the design. Though a bit tedious, this is a familiar process to most prepress artists.

One well-known software developer is Esko. They have a barcode solution that is unique for three main reasons:

- It is a tool you can use within Adobe Illustrator®. No more jumping in and out of different software solutions to create, import, and make changes. The artist works within Illustrator® to create and/or make changes.

- What really sets it apart, is that the barcode generated is not an raster image file, but rather vector art that is automatically placed in a separate non-destructive art layer. Since it is vector art it is easy to change things, like the barcode’s color for example, similar to how other vector art is manipulated using native Illustrator® tools.

- But even more impressive is the barcode panel, which allows the user to dynamically create or update a barcode. Using this panel, the operator can conveniently edit the barcode’s color, size, magnification, number, etc.. They can even customize the font and placement of the human readable characters (see image 4).

Let me reiterate, all of this is accomplished without ever leaving Illustrator® and is built on a non-destructive art layer. Every change made in this panel is immediately reflected by the barcode within the art file.

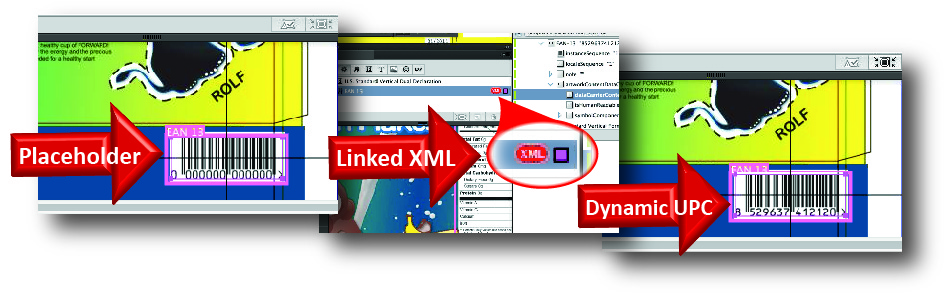

Pretty nice, but you may be thinking that it would be even better if the prepress artist didn't have to enter the UPC code at all. It would be great if the art could be dynamically linked to a code provided by the CPC, right? With Esko’s suite of tools, this too is possible, by creating a vector barcode as a placeholder using their dynamic tools. This can then be linked to a customer provided XML file with the correct code information, which usually comes from the brand manager (see image 5). As you can see, each part of this dynamic tool set allows the artist flexibility and yet builds in layers of protection to minimize errors and maintain regulatory compliance.

Consumed With What We Eat

So I have already mentioned, a couple times now, the recent nutritional panel changes. This marks the first major change since 1993, if you don’t count the 2006 change to add trans fat to the nutrients. Now released, our industry will have two years (26 July 2018) to make sure labels and packaging are in compliance. As CPC’s start to define changes for their product lines, we can certainly expect a to see a gradual escalation in urgency to adopt the new regulations and ensure all product labels conform.

For those of us in packaging who actually generate these tables the thought of changing ALL the nutritional panels for ALL the products we manage may be a daunting and tedious task to face. These changes will involve the shifting, adding, removing and rekeying of a lot of information, not to mention potentially having to adjust positioning of text and other art elements that surround the nutrition facts. ...Ugh!

Are there options to automate this too? Well, YES there are! ...

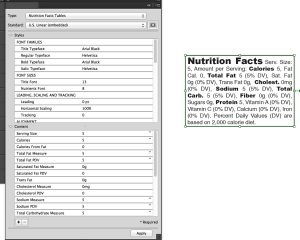

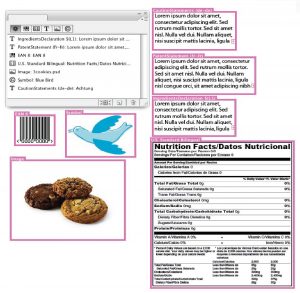

If you have been building these tables manually, this would be a good time to consider investing in a solution that will allow you to dynamically build and populate this information. Many of you may already be using a cloud-based solution or other software specifically developed for building nutritional panels. Once again, Esko offers a unique tool for easily building and changing nutritional panels in a non-destructive art layer. This dynamic tool is another Adobe Illustrator® plug-in and includes access to all types of panel formats for which you can manually type in the desired values or link the table with XML data to automatically populate the information. Since all the tools reside within Illustrator® the operator can effortlessly move between tools and does not need to open other applications or go through the process of placing images and then repositioning the art.

Image 6 shows the U.S. Linear nutritional panel format. It is easily dynamically customized to remove the cholesterol measurement field or convert it to the U.S. Standard Full format (see Image 7). While the nutrition data stays the same you can see the style in which it is displayed is very different. Similar to Esko’s barcode tool, the changes are made via the panel and the art immediately reflects the changes so the artist never has to leave Illustrator®, thus making the art itself dynamic.

My Art is Smarter then Your Art

I get the feeling you'd rather consider governmental regulations and the implementation of all these standards as “opportunities”, but to do that, you need to be able to manage your frustration, confusion and fear so that it is as simplified a process as it can be. While the brand colors and images are definitely important, as this is what grabs the consumer’s attention from the shelf, errors with simple line art (like barcodes, ingredients, nutritional info, etc.) can sting way more then any color shift. There are plenty of resources you can research and purchase or use online, but removing as many touch points as possible is the ultimate key to success. This is why dynamic content makes so much sense. The ability to draw XML data from other systems and then link the XML data to placeholders within your file helps to eliminate additional touch points. That is one less thing the operator has to key-in and that means one more chance to make a mistake is averted.

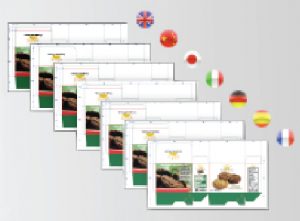

I have already touched on this briefly with barcodes, but any art can be made intelligent and dynamic. By tagging the art element as dynamic, it becomes a placeholder (see image 8). This placeholder then acts as a bridge linking it with intelligent content (XML data created by a CPC’s content management system) to the file. In essence the design is made “smart”, triggered by dynamically linked art elements. A placeholder barcode (made of all zeros) becomes a live barcode. A nutritional panel or ingredients list is populated with content. An image element is replaced with the correct or updated art. Multiple versions of a product are dynamicically adapted (see image 9).

But wait! It gets even better! The next stepping stone is to connect this to a web-portal to make this a cloud-based solution. Combining a web-portal with dynamic art, the operator can invite and collaborate directly with the CPC and others. This especially makes good sense when it comes to governmentally regulated art for things like barcodes, nutritional panels and ingredients list. Lawyers, brand managers, marketing groups, these are the people in the know and why not try to streamline this process and allow them direct access to help mange specific content.

Wrapping Things Up

Here are a few key things to consider when selecting your ideal solution:

- Tools reside within Adobe Illustrator®

- Art is built on a non-destructive art layer

- Content is locked so it is protected from accidental, non-deliberate changes

- Changes are instantly mirrored within the art file via dynamic links

- Elements can be linked to XML data provided by the brand owner/manager

- A window can be opened allowing the prepress supplier to link other key individuals and decision makers as the package/label is being created

These things will all go a long way to improving efficiencies. Think of the time an operator can save by not having to jump back and forth between applications, removing the old and then adding and repositioning new art. Hopefully these solutions not only provide a little piece of mind, but also make the prepress supplier an even more valuable asset to the CPC. Regulations are going to continue to change as these groups (like the FDA, USDA, GS1, EPA, etc) work to improve and adapt packaging to our evolving understanding of business needs, consumer health and the products being packaged. Most software developers are doing their part to stay in the loop and keep their solutions relevant. What helps protect you as the prepress supplier is having solutions and tools that make it simple and keeping those systems current so you have access to new formats and requirements based on the latest and greatest regulations.