TSG Research Project:

Mylar Dimensional Stability Under Excessive Dryer Heat

Does excess dryer heat compromise the dimensional stability of the mylar backing. TSG feels that pushing the temperature higher could push the limits of thermal stability of the backing foil of the flexo printing plates. The recommended drying temperature is limited, as the raw polymer materials have a glass transition temperature* at > 158°F (70°C) and an irreversible dimensional change occurs in this temperature range. The glass–liquid transition or glass transition for short is the reversible transition in amorphous materials from a hard and relatively brittle "glassy" state into a viscous or rubbery state as the temperature is increased. The glass-transition temperature Tgof a material characterizes the range of temperatures over which this glass transition occurs. It is always lower than the melting temperature, Tm, of the crystalline state of the material, if one exists.

Equipment, Material and Measurement Devices Used

- G&J Flex-in-One 260

- Esko CDI (HD Flexo)

- LAVA Thermal Processor

- ITP-M – 0.067

- Systec Video Mounter

Process Description

- Mounted the thermally processed plate cross-hairs so they lined up inside the digitally generated mounter cross-hair targets. Locked cameras into position for the duration of this trial.

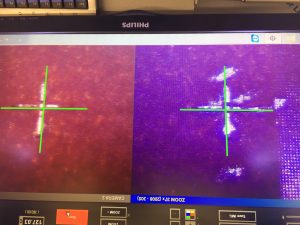

- Set dryer temper to 80ºC (176ºF) and dried the above mentioned plate for 90 minutes.

- Removed plate from the dryer and immediately mounted to same camera position on the mounter.

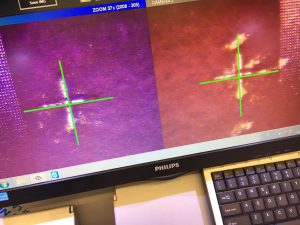

- Checked them again after cooling to room temperature and resting an additional 12 hours.

Data and Results

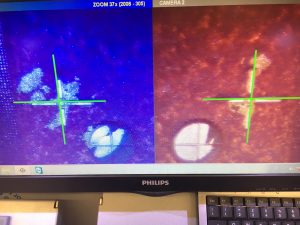

Before heating the plate cross-hairs fell within the green camera cross-hairs.

After heating the plate to 79ºC the plate cross-hairs fell outside the green camera cross-hairs.

After allowing the plate to cool to room temperature and rest the plate cross-hairs did not move and still fell outside the green camera cross-hairs. Dimensional stability was permanently compromised.

Summary:

Overheating the plate lead to a change of about 0.012” over about 17.5” width. Even after cooling the dimensional stability was permanently compromised.

APR Technical Solutions Group

We formed our Technical Solutions Group (TSG) to encompass our full range of expertise in all critical areas of the flexo process. This team is made up of industry professionals who are dedicated to being up to date on new technologies, armed with the last in diagnostic tools, and experienced in problem solving that can achieve sustainable results. All of the TSG team members are FIRST Level III certified. Dan Muthig has over 29 years experience in narrow to wide web flexo.