Why is this important?

If rotational speed does have an effect on outward force, then one could surmise that with increased press speed we will see more force between the photopolymer printing plate and the impression cylinder or drum. The answer to the question is "yes." So why is this important to consider? Well consider this, if I set and lock-in my ink and impression settings at a relatively slow speed in order to better evaluate the transfer of the ink to plate and substrate, and then I bring the press to run speed I have now added impression from the plate to the substrate (and impression cylinder/drum). I decreased the distance in between the two complete finished diameters (CFD). In short, the plate is now squeezed. Those who understand this dynamic tend to quickly adjust or tweak these settings once the press has been brought up to full press speed. FF>>> if you don't care about the math to "In the Weeds" with Naysayers

The math behind the adjustment process

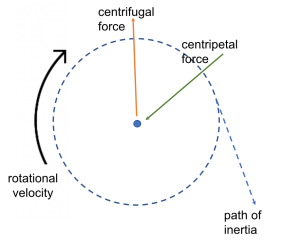

What we see below is the math behind centrifugal force. Now before any of you conspiracy theorists start calling me out and stating that there really is no such thing as centrifugal force, please just hear me out. When an object travels in a circle it behaves as if it was experiencing an outward force which is known as the centrifugal force and depends on the mass of the object, the speed of rotation, and the distance from the center.

Calculating Centrifugal Force (F=mv2/r):

- Find the mass of the object - for example, 80 lbs.

- Determine the radius of rotation. Let's assume it's a 18.25" print repeat, so the complete radius would be (18.25"/π)/2 = 2.9" or .24 ft.

- Determine the velocity of the object. Let's assume it is 325 fpm.

- Force equation: mass x velocity2 / radius. In our example, it will be equal to 80 lbs. x 325 fpm2 / .24 ft. (F) force = 304 lbf (pounds of force)

Calculating Centrifugal Acceleration (A=f/m):

- Find the centrifugal force - in the case above, 304 lbf

- Find the mass of the object - for example, 80 lbs.

- Acceleration equation: (A) acceleration = force / mass. In our example, 304 lbf. / 80 lbs. = 3.8 fps2

"Into the Weeds" with the Naysayers

A couple of times I have been called out by people with a better understanding of physics than myself. Their objection is that centrifugal force (by definition) is when an object travels in a circle it behaves as if it was experiencing an outward force. In actuality, if you tie a rock to a long string and swing it over your head in a circle - if you cut or let go of the string it would not travel outward from the center of the circle but would continue in the path of inertia. My first thought was whoa...they are right. But what about when we are in a car traveling in a sharp radius at high speed, or we are on an amusement park ride - I have certainly felt my mass pressing outward.

The answer is that centrifugal force only exists when the centripetal force is present. Centripetal force a force that acts on a body moving in a circular path and is directed toward the center around which the body is moving. In my examples above it would be the car door or wall of the cockpit of the amusement ride. In the case of a photopolymer plate mounted on a print cylinder or sleeve the points of centripetal force is the impression roll and anilox roll. If the print cylinder was rotating even at a high velocity but not engaged to the anilox or impression roll/drum there would be no centripetal force and therefore no centrifugal force.

What does it all mean?

It means that as you increase or decrease press speed you have an effect on centrifugal force and therefore impression. It also means that the heavier or more mass of the print cylinder and printing plate the greater impact there will be on this effect. In an ideal environment, we could calculate this effect and adjust as press speed is altered. After all, it's just math so there must be a formula that can tell us that based on weight and speed how many "clicks" do I take impression in or out. In theory, you could do this. However, there are many factors that also affect the printed result of this speed change. The hardness of the plate and the level of compressibility of the mounting tape are key factors. Whether or no the photopolymer plate is a standard digital plate or if it is a flat-top dot plate that by design absorbs some over-impression. Here's a couple of examples;Scenario A

- Materials; 24" x 40" (.067") flat-top plate, med-soft tape, and 42 lb. print sleeve

- Press speed; Impression settings set at 75 fpm, once achieved press speed was increased in increments of 200 fpm up to 875 fpm

- 75 to 275 fpm - no effect

- 275 to 475 fpm - no effect

- 475 to 675 fpm - required to back off "2 clicks" (-.0004")

- 675 to 875 fpm - no effectrequired to back off "1 click" (-.0002") total -.0006"

Scenario B

- Materials; 24" x 40" (.067") standard digital plate, med-soft tape, and 51 lb. print sleeve

- Press speed; Impression settings set at 75 fpm, once achieved press speed was increased in increments of 200 fpm up to 875 fpm

- 75 to 275 fpm - required to back off "2 click" (-.0004")

- 275 to 475 fpm - required to back off "1 clicks" (-.0004") total -.0006"

- 475 to 675 fpm - no effect

- 675 to 875 fpm - required to back off "3 clicks" (-.0006") total -.0014"

If you want to learn more about this subject, please feel free to reach out to us by calling 1-800-445-4017, or by e-mail at [email protected].

All Printing Resources has formed our Technical Solutions Group (TSG) to encompass our full range of expertise in all critical areas of the flexo process. This team is made up of industry professionals dedicated to being up-to-date on new technologies along with best practices. They are armed with the latest in diagnostic tools and are experienced in problem-solving that can achieve sustainable results. The TSG has walked in your shoes, and have felt your pain.