Flexible Service, Precise Results

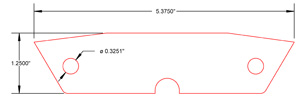

All of our end seals are cut from CAD drawings (either produced by APR from parts supplied or from customer supplied drawings), allowing for exact repeatability, fast turnaround when changes are needed, and no die costs.

We have found that end seal failures often are caused by inaccurate designs.

Corrections can be achieved by slightly modifying the size of the end seal, the radius and/or changing the end seal bevels so that the doctor blades change their level of contact to the anilox rolls.

APR has developed a unique methodology to make sure that the end seals we produce are the right fit for their specific application.

More about End Seals from APR.