tesa® Process Tapes for Printing

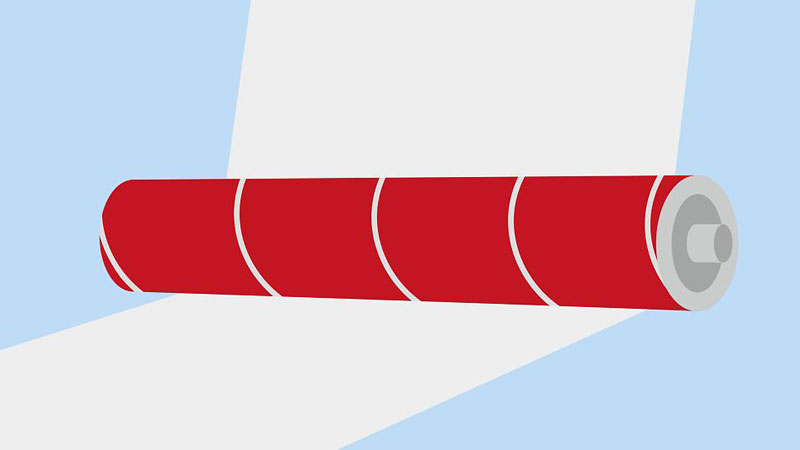

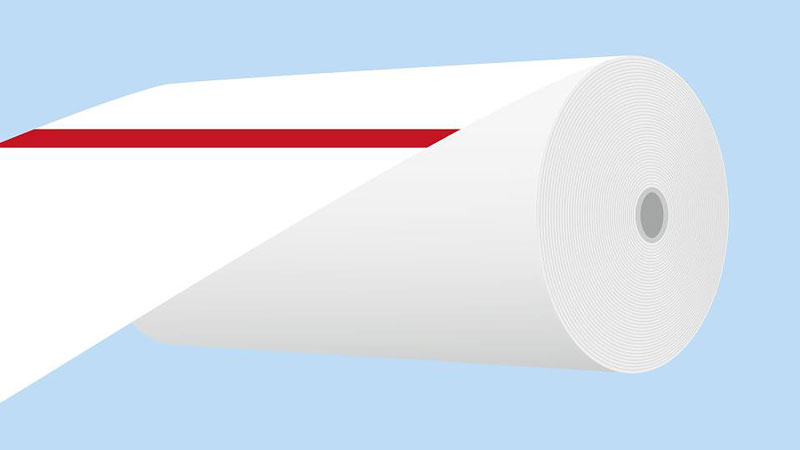

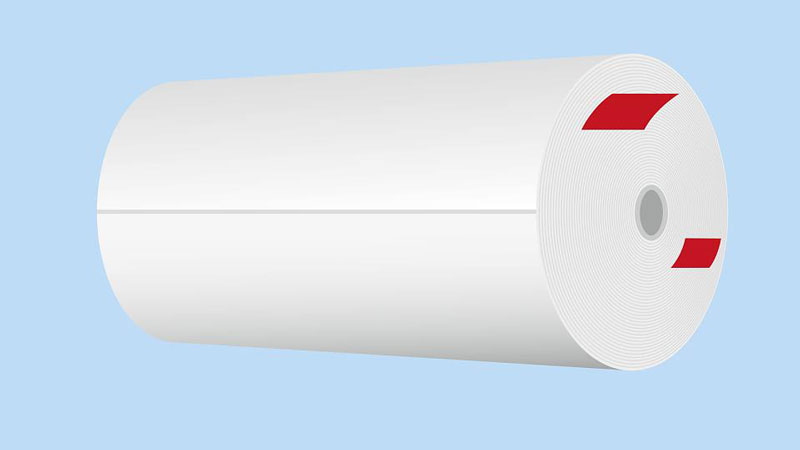

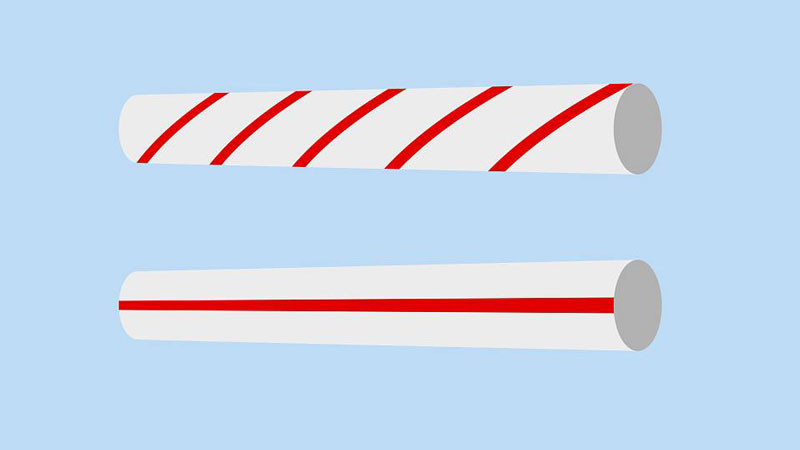

Roller wrapping, plate edge sealing, core starting, and failure flagging are just a few examples from our wide range of complementary tapes.

Complementary Products for Flexographic Printing

Efficiency is key to profitability. Complementary solutions based on pressure-sensitive adhesive technology speed up changeovers, prevent machine stops, and facilitate everyday tasks.

Roller wrapping, plate edge sealing, UV measuring, plate cleaning, or failure flagging tapes facilitate an efficient and reliable printing process and are just some examples of the well-conceived solutions tesa offers in addition to plate mounting tapes and splicing tapes for flexographic printing.

The experienced and globally active tesa sales staff, supported by laboratory researchers and engineers, can provide you with ideas and solutions to identify opportunities for higher productivity and to eliminate process disturbances.

Products

| Product | Backing material | Type of adhesive | Total thickness | Elongation at break |

|---|---|---|---|---|

| tesa® 4104 colored | PVC film | natural rubber | 2.63 mils | 60 % |

| tesa® 4104 transparent | PVC film | natural rubber | 2.55 mils | 60 % |

| tesa® 4137 | PET film | acrylic | 1.96 mils | 140 % |

| tesa® 4244 PV2 | PVC film | natural rubber | 5.39 mils | 252 % |

| tesa® 4287 | TPP | natural rubber | 2.69 mils | 35 % |

| tesa® 4287 | TPP | natural rubber | 3.11 mils | 35 % |

| tesa® Printer's Friend 4563 PV3 | Silicone-coated cloth | natural rubber | 14.96 mils | |

| tesa® Printer's Friend 4863 PV3 | Silicone-coated cloth | natural rubber | thickness | 24.4 mils |

| tesa® 64621 Industry | PP film | synthetic rubber | 3.54 mils |

Product Data sheets

(Adobe Acrobat PDFs, require Adobe Reader)

roller-wrapping-tesa-printers-friend.pdf

tesa-softprint-plate-mounting-solutions-for-flexographic-printing.pdf