Dirty print is something many flexographic printers may struggle with. An online search will reveal quite a few cause and effect diagrams or charts for possible solutions for the common issue. In some cases printers go through the gamut, making sure their ink is in spec, dryers are balanced, adding slower drying solvents to the ink, swapping anilox rolls with different volumes, and in some cases trying plate materials with different release properties. And yet the problem still exists, at least to some degree.

Often left out of the trouble shooting process for dirty print is the doctor blade. It is certainly important to be sure the ink is in spec, correct anilox rolls are in the press and the dryers in balance. However, before messing around changing plate material or trying to play a chemist with the ink formulation, take a more in-depth look at the doctor blade. Especially if the print starts out clean and progressively get dirtier as the job goes on. After all, the blade along with the anilox are responsible for applying a consistent ink film thickness to the printing plate surface.

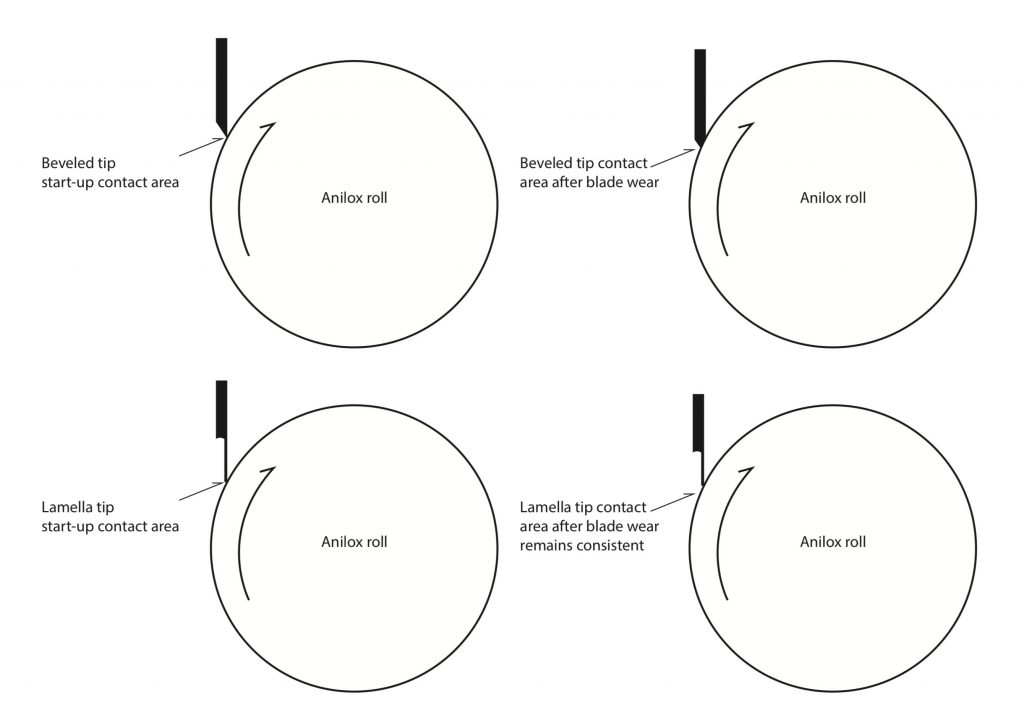

There are many tip configurations on doctor blades, and all have their purpose. Sometimes, it’s not a one size fits all scenario. Dirty print can often be more prevalent in process or screened areas, where a thin, consistent ink film thickness is more critical. As round tip or beveled tip blades wear, the contact area of the doctor blades on the anilox roll grows affecting the thickness of the ink film. As the contact area grows, the ink film thickness also grows, sometimes to the point that too much ink is being applied to the plate surface and the result can be dirty print along with increased ink density as well.

Machined blade tips, such as lamella tips and stepped tips can offer cleaner print by keeping a consistent contact area with the anilox throughout the life of the blade. Controlling the contact area also controls the ink film thickness, resulting in cleaner print and consistent ink densities throughout the run.

All Printing Resources has formed our Technical Solutions Group (TSG) to encompass a full range of expertise in all critical areas of the flexo process. This team is made up of industry professionals dedicated to being up-to-date on new technologies along with best practices. They are armed with the latest in diagnostic tools, and are experienced in problem-solving that can achieve sustainable results.