2018 is here - what's your resolution?

Plate imaging resolution is more important now than ever. With flat top plate technologies advancing to hold extremely fine detail, adding HD imaging capabilities to your platemaking can greatly boost print quality.

The Details - Highlights and Fine Type

Highlights and fine type are two classic problem areas for flexo printers. The fundamental design of our printing process makes it highly susceptible to excessive dot gain, causing highlights to print heavy and fine type to fill in and become illegible. There are many ways to attack this problem, and the solution lies in finding the right combination of imaging technology, plate material, and press settings.

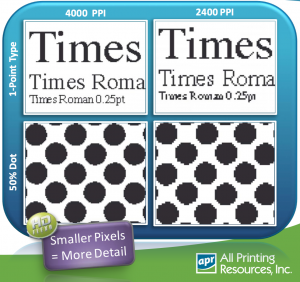

Plate imaging is a key component - after all, if the process does not start with a high quality image on the plate, how can we expect a high quality print result? Today's digital plate imagers, such as the Esko CDI Crystal, provide high quality imaging at resolutions of 4000 PPI (and higher) to ensure that every detail is accurately translated to the digital plate mask (via LEN file - see Image A).

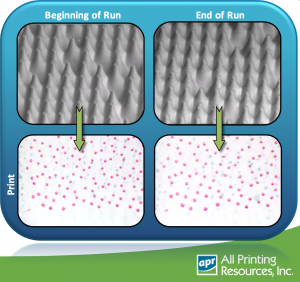

This is where the plate material becomes a critical component in the process. Since traditional digital flexo plates are effected by oxygen inhibition, they do not form a true 1:1 image of the information ablated into the digital mask. For maximum quality on the finished plate, a flat top plate must be used. MacDermid is the leader in flat top dot technology with their Lux In-The-Plate (ITP) technology. Combining high resolution imaging, Lux flat top plates, and Esko HD Flexo highlight screening patterns results in a smooth and consistent fade to zero, that lasts through the print run and beyond (see Image B).

More Than Just Dots ...

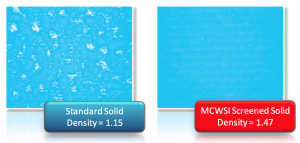

For some, an even larger hurdle in the flexo printing process is ink coverage. Particularly in wide web film, problems such as low ink density, edge void, and pinholing can cause downtime. Another unique advantage to the combination of Lux ITP flat top dot plates and high-resolution imaging is the opportunity for ink transfer optimization. Through the implementation of Esko's Pixel+ screening, 90 unique settings are tested simultaneously to find the best result. This in combination with MacDermid's ink-releasing polymer formulations can provide exceptional results. APR's TSG has seen great improvements for many printers through print trials, especially in the areas of eliminating mottle/pinholing and edge void (see Image C).

Implementing this imaging and platemaking process may seem like a daunting task, but APR's TSG has the experience and training skills to make the transition as smooth and painless as possible. We specialize in educating our customers while implementing new technologies. If you're interested in finding out how these exciting products can improve your print quality and productivity, contact us here.

If you would like to download the full presentation on this topic, click here.