- Safely and Automatically Flags Defects

- Flags at Speeds Over 4,000 Feet/Minute

- Accurately and Reliably Applies Flags

- Connects to All Inspection Systems

- Tracks Defects From Upstream Locations

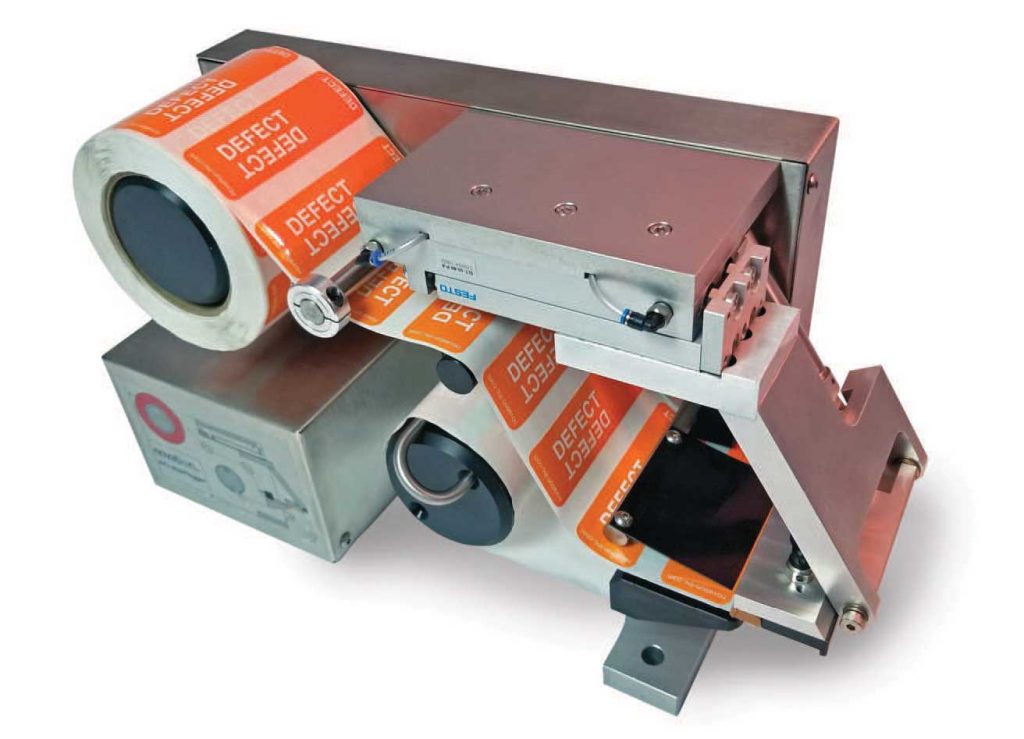

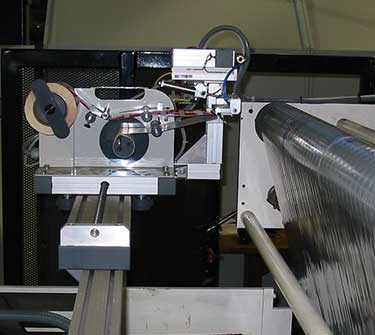

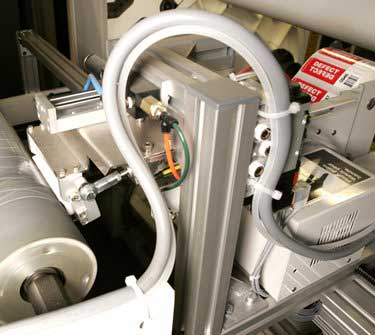

The AF3 WebFlagger has become an industry-standard in defect marking. Novation’s AF3 WebFlagger automatically applies a pressure sensitive label or “flag” to almost any type of web moving at virtually all process speeds. The AF3 safely and accurately flags webs moving at speeds up to and above 4,000 fpm (1,200 MPM). The flags have the adhesive deadened on the portion which hangs off the web’s edge to prevent the exposed portion of the flag from sticking to machine parts such as idler rolls, or from folding back onto itself. The flags also have a film lamination for strength. A flag can be triggered to be applied by either an operator with the press of a button or from almost any machine signal. There are five additional inputs that can be utilized for customer connections.

Machine functions such as unwind splices can be used to trigger the AF3 WebFlagger. The AF3 can also connect to virtually any inspection system. The AF3 can be configured to track any input from a pushbutton, machine signal, or inspection system. When the WebFlagger is configured this way, upon receiving the signal from an upstream device, it will wait to apply a flag until the web has traveled a preset distance. That is until the defect arrives at the location of the WebFlagger. If the process has a web width which varies, the AF3 WebFlagger can be mounted on an optional, adjustable slide base. This slide base allows the WebFlagger to be easily adjusted from side-to-side with a handwheel, allowing it to be lined up to the edge of different width webs.

- Applies Pre-printed, Individually Numbered Flags

- Records the Location, Type, and Length of Defects

- Creates Roll Maps with the Data Collected

- Prints a Report or Uploads Roll Maps to a Plant LAN

- Data Can be Used to Create Efficiency Reports

ScrapTracker is a system which creates a data file or “roll map” associated with each roll of material manufactured, processed or printed. The data file contains all the information about the locations and types of any defects within the roll. ScrapTracker uses the AF3 WebFlagger to apply flags with unique ID numbers. The flags are pre-printed with a unique number and a corresponding bar code. A flag can be triggered by an operator pushbutton or a signal from the machine. When a flag is signaled to be applied, the flag’s ID number is recorded along with the type of defect and its location within the roll. Six different types of defect can be logged. ScrapTracker creates a roll map for each roll produced in the form of a data file. This data file can be printed as a report or uploaded to plant LAN or any data storage device.

The roll report created can be used in the subsequent process to help identify the type of defect to be inspected and/or removed. If the downstream process is equipped with our RollCode system, the roll map data is used to automatically stop the machine at each flagged location. The data in the roll map can also be used to create custom reports for scrap. Reports such as total amounts of scrap, scrap by machine, shift, month, etc. can be generated. These reports allow a quality control department easy access to this valuable data used for process improvement and scrap reduction programs.

- Connects to Downstream Processes Like Slitters and Roll Edit Machines

- Downloads the ScrapTracker Roll Map

- Stops the Downstream Process at Each Flag and at the Roll’s End

- Identifies the Defect Type at Each Flag

RollCode is a system which connects to a machine such as slitter or roll doctoring machine, or wherever rolls needing scrap removed are processed. With RollCode an operator no longer needs to be stationed at the unwinding roll to look for upcoming flagged locations to stop the machine at the flags.

RollCode uses the information contained in a roll map created by our ScrapTracker system to automatically stop any of these machines at each defect flag and at the roll’s end. A touch screen operator interface displays the roll map information including the flag number, the defect type, and the location of the defect within the roll.

The typical manual process of stopping at flags involves the operator running the machine slowly to watch for the next flag, guessing when to hit the stop button, and then jogging the machine to the final location. Since the machine stops automatically at every flag, it can run at maximum process speeds between stops thereby maximizing machine run time and minimizing operator labor.

Because of the wide variety of processes and materials requiring automatic flagging, we offer a variety of pressure sensitive flag styles. Variounters colors, adhesive styles and constructions are available for use with the AF2 WebFlagger.

The flag’s adhesive is deadened on the portion which hangs off the edge of the web and protrudes out of the wound roll. This prevents the flags from sticking to idler rolls or any other object. To ensure the flags are tough enough to survive in a manufacturing environment, they are also over-laminated with film after printing.

Some flags utilize a very aggressive permanent adhesive while others use a removable style. One flag has a metallic lamination for automatic sensing on a downstream process; another is printed with an individual number and corresponding bar code. These numbered flags are for use with the ScrapTracker system or a third party inspection system for unique identification of each defect location. The chart below lists our standard flag styles which are typically available for immediate delivery.

Defect Flag Styles

| Description | Part No. |

|---|---|

| Orange – Permanent Adhesive – Right Hand | AF2-RH-PO |

| Orange – Permanent Adhesive – Left Hand | AF2-LH-PO |

| Yellow – Removable Adhesive – Right Hand | AF2-RH-RY |

| Yellow – Removable Adhesive – Left Hand | AF2-LH-RY |

| Blue – Removable Adhesive – Right Hand | AF2-RH-RB |

| Blue – Removable Adhesive – Left Hand | AF2-LH-RB |

| Red – Permanent Adhesive – Right Hand – Metallized | AF2-RH-PRM |

| Red – Permanent Adhesive – Left Hand – Metallized | AF2-LH-PRM |

| ScrapTracker – Numbered and Bar Coded, Removable Adhesive – Right Hand | RC-RH-R |

| ScrapTracker – Numbered and Bar Coded, Removable Adhesive – Left Hand | RC-LH-R |

| Gold – Metallized – Full Width Permanent Adhesive (No Deadened Adhesive, Laminate or Print) | AF2-MTL |

Note: All rolls contain approximately 1000 flags.

Downloads

Novation Product Guide - Adobe PDF 1.7 MB

AF3 WebFlagger Brochure - Adobe PDF 628 KB

ScrapTracker Brochure - Adobe PDF 588 KB

RollCode Brochure - Adobe PDF 542 KB

Flag Styles Brochure - Adobe PDF 746 KB

Adjustable Slide Base for AF3 WebFlagger Brochure - Adobe PDF 788 KB