3M™ Scotch-Weld™ Hot Melt Bonding Systems

Easily apply 3M™ Scotch-Weld™ Hot Melt Adhesives 3762LM, 3776LM, 3792LM, or 3798LM with a 3M™ Scotch-Weld™ Hot Melt Applicator LT to seal plate edges against ink and solvent penetration that can cause edge lifting.

™ Hot Melt Applicator LT

LT with Quadrack Converter

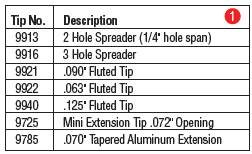

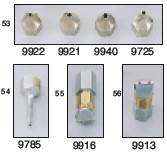

3M™ Scotch-Weld™ Accessories and Applicator Tips

| 3M™ Scotch-Weld™ Hot Melt Applicator |

Weight | Output lb/hr |

Adhesive Size dia. x length |

Accessories (keyed below) |

|||

|---|---|---|---|---|---|---|---|

| LT | 10.0 oz | 2.6 | 5/8 x 2" | ||||

| LT with Quadrack™ Converter |

13.8 oz. | 2.6 | 5/8 x 8" | ||||

| Temperature: 265°F (129°C) | |||||||

Increase capacity and ease of operation with Quadrack Converter and Palm Trigger.

Heavy-Duty Benchstand for added convenience.

A general purpose tip (9921) is supplied with each 3M™ Scotch-Weld™ Applicator. Optional tips are available to increase productivity.

Multiple options with 3M™ Single Coated Tapes

3M™Aluminum Foil Tape 425, 3M™Vinyl Tape 471, or 3M™ Polyester Film Tape 850 are pressure sensitive adhesive tapes that bond on contact to seal plate edges against ink and solvent penetration that can cause edge lifting.

3M™ Aluminum Foil Tape 425

3M™ Vinyl Tape 471

To seal plate edges against ink and solvent penetration that can weaken mounting tape strength, 3M™ Aluminum Foil Tape 425 (left) and 3M™Vinyl Tape 471 (right) apply easily, bonding on contact and conforming over the plate edge.

Product Information

| 3M™Scotch-Weld™ Hot Melt Adhesives (Color) |

Features Application Ideas |

Sizes | Delivery Time(sec) for 1"x3" Cartridge |

Heat Resistance (°F/°C) |

Peel Strength PIW(1) 72°F (22°C) |

Shear Strength PSI(2) 72°F (22°C) |

Open Time 1/8" Bead (Sec)(3) |

|---|---|---|---|---|---|---|---|

| 3762LM* Lt. Amber |

Economical, fast setting general purpose |

5/8" X 8" 5/8" X 2" |

45 | 130/54 | 6 | 480 | 25 |

| 3776LM Tan |

Bonds variety of materials | 5/8" X 8" | 45 | 140/60 | 9 | 600 | 40 |

| 3792LM* Clear |

Clear, Multi-purpose | 5/8" X 8" 5/8" X 2" |

57 | 140/60 | 13 | 350 | 40 |

| 3798LM Clear |

Gummy glue removable adhesive |

5/8" x 2" | N/A | 120/49 | N/A | N/A | 30 |

* Also available in bulk. (1) On canvas (2) On Douglas Fir (3) 1/8" semicircular bead, Douglas Fir to Douglas Fir.

Note: This technical information and data should be considered representative or typical only and should not be used for specification purposes.

Product Information

| Product/ Color |

Tape Structure (Backing/ Adhesive) | Backing Thickness mils (mm) | Total Thickness mils (mm) | Adhesion to Steel oz./in. (N/100 mm) | Tensile Strength lbs./in. (N/100 mm) | Elongation at Break % | Temperature Range °F (°C) | Comments |

|---|---|---|---|---|---|---|---|---|

| ASTM Test Method: |

D-3652 | D-3652 | D-3330 | D-3759 | D-3759 | |||

| Premium Performance Aluminum Foil Tape | ||||||||

| 425 | Aluminum/ Acrylic | 2.8 (0.07) | 4.6 (0.12) | 47 (51) | 30 (525) | 8 | -65 to 300°F (-54 to 149°C) |

Most versatile aluminum tape.1, 2, 3, 4 |

| Premium Performance Vinyl Tape | ||||||||

| 471 /Various Colors |

Vinyl/ Rubber | 4.1 (0.10) | 5.2 (0.13) | 23 (25) | 16 (280) | 130 | 40 to 170°F (4 to 77°C) | Conformable and clean removal. Black, Blue, Brown, Green, Orange, Puple, Red, Transparent, White, Yellow |

| General Industrial Tapes | ||||||||

| 850 /Transparent |

Polyester/ Acrylic | 0.9 (0.02) | 1.9 (0.05) | 30 (33) | 28 (491) | 120 | -60 to 300°F (-50 to 150°C) | Splicing, holding, sealing, highly transparent. |

| 850 /White /Red /Blk |

Polyester/ Acrylic | 0.9 (0.02) | 1.9 (0.05) | 30 (33) | 28 (491) | 120 | -60 to 300°F (-50 to 150°C) | Splicing, holding, decorating, color-coding, sealing. |

| 850 /Silver /Gold |

Metallic Polyester/ Acrylic |

0.9 (0.02) | 1.9 (0.05) | 42 (46) | 28 (491) | 120 | -60 to 300°F (-50 to 150°C) | Splicing, holding, decorating, color-coding, sealing. |

(1) Can be qualified to L-T-80B,MIL-T-23397B II; (2) Meets U.L., Class L File R 7311; (3) F.A.R.25.853; (a) (4) Meets U.L.746C File E122798;

Note: This technical information and data should be considered representative or typical only and should not be used for specification purposes.

3M Tape Home | Flexomount Solid Printing Tape | Cushion-Mount Solid Printing Tape | Cushion-Mount Plus Combination Printing Tape | Cushion-Mount Plus Process Printing Tape | Cylinder Mount Build-Up Tape | Thin Tapes | Edge Sealing Tapes | Plate Mounting Techniques (PDF)