CAMIS Plate Mounters and Demounters

Optimize your tape & plate application to reap on-press rewards in uptime and improvements in print quality and repeatability.

Plate Mounters

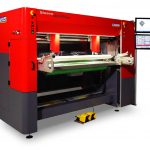

SLEEVE MASTER AUTO

SLEEVE MASTER AUTO (SMA) offers "Hands free” plate registration and application to gain the maximum productivity of the pre-press department. CAMIS repeatability and reliability included. The aim of the SMA is to deliver to the operator a new tool, that is able to deliver automation without the issues often linked to this kind of technology

- With maximum machine and process reliability

- User friendly interface based on the Irisleeve HD platform

- Updated MMRM imaging software for camera / image management

- Full hands free plate registration

- Full hands free plate application (even used plates)

- The ability to manually override all systems and mount either by ‘push botton’ or by ‘hand’ (complete machine/mounting dependance)

Download: Camis SLEEVE MASTER AUTO and DEMOUNTER DMTS - Adobe PDF, 470KB

IRISMALL

CAMIS IRISMALL is a cost effective and versatile narrow web mounter suitable for sleeves, cylinders and shells thought interchangeable or dedicated tooling. Simple and easy to use, it achieves dot on dot registration quickly without complications, but bringing into the narrow web market all the main features of our mid to wide web mounters

Characteristics:

- Printing width: up to 730mm or 850mm (sleeve)

- Printing repeats: 250mm > 800mm

- 2 manual cameras

- Wide screen monitor for easy mounting references tracking

- 2 digital indicators to guarantee accurate and repeatable camera positioning

- Front and back mounting table

- Sleeve dedicated version

- Shell sleeve dedicated version

- Removable sleeve mandrel for combinated mounting

- Plate pressure roller (option)

- Pneumatic dividing gear (on sleeve only configuration)

Download: Camis IRISMALL Mounter - Adobe PDF, 2.3MB

IRISLEEVE HD

IRISLEEVE HD has “Total Workflow control” that ensures each operator mounts “press ready” sleeves perfectly every time, quickly and efficiently with utmost reliability and HD precision

Characteristics:- Printing width: 600 to 1900mm

- Printing repeats: 300mm > 1300mm

- Different camera configurations

- Wide screen monitor for easy mounting references tracking

- Digital indicators to guarantee accurate and repeatable camera positioning (manual cameras only)

- Front and back motorized mounting table

- Plate pressure roller

- Full servo system with numeric control unit, brushless servo motor drives and advanced HMI interface

- Taper Slide powered tape applicator up to 1420mm wide

- Adjustable cutting knife

- Advanced video package MMRM

Download: Camis Plate Mounting Solutions - Adobe PDF, 1.5MB

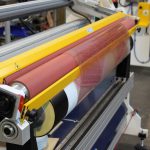

IRIFLEX

CAMIS IRIFLEX is a flexible cylinder and sleeve mounting system, available in 2, 4, 6 manual cameras or full servo drive 2 cameras. It’s also available with the proofing test feature as option. Its “Total Workflow control” ensures that each operator mounts “press ready” sleeves or cylinders perfectly every time, quickly and efficiently with utmost reliability and HD precision

Characteristics:

- Printing width: 600 to 2500mm

- Printing repeats: 300mm > 1250mm

- Different camera configurations

- Wide screen monitor for easy mounting references tracking

- Digital indicators to guarantee accurate and repeatable camera positioning (manual cameras only)

- Front and back motorized mounting table

- Plate pressure roller

- Different camera configurations

- Full servo system with numeric control unit, brushless servo motor drives and advanced HMI interface

- Taper Slide powered tape applicator up to 1420mm wide

- Adjustable cutting knife

- Advanced video package MMRM

- Servo driven Proofing drum to perform proofing test of the plates

Download: Camis Plate Mounting Solutions - Adobe PDF, 1.5MB

Plate Demounters

DEMOUNTER DM

CAMIS DM removes plates & tape from flexographic printing sleeves, drastically reducing time and also damages and fatigue associated with manually removing plates and tape at the end of a lengthy plate run

- Reduce Damage to plates

- Reduce operator fatigue

- Increases the productivity of the plate mounters, removing the plate and tape removal operations from their workflows

- Handles all sleeves with care

- Increase speed and quality to press

- Sleeve width: up 1000 / 1500 / 1800 / 2200 mm

- Printing repeats: 260mm > 1250mm (10,25” > 49”)

- Sleeve adjustable hydraulic supports

Download: Camis DM Demounter - Adobe PDF, 2.3MB

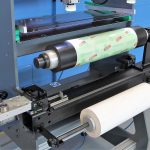

DEMOUNTER DMTS

To optimize the workflow in the prepress stage, the CAMIS DM system may be merged with our tape applicator TAPER SLIDE. This is the CAMIS DMTS. CAMIS DMTS removes plates & tape from flexographic printing sleeves, drastically reducing time and also damages and fatigue associated with manually removing plates and tape at the end of a lengthy plate run.

Specifically designed for sleeve presses, the DMTS uses the original and hugely effective powered tape applicator, the TAPER SLIDE, to remove the manual tape application issues to ensure that all types of tape are mounted perfectly on all sleeves.

- Reduce Damage to plates

- Reduce operator fatigue

- Increases the productivity of the plate mounters, removing the plate removal and tape operation from their workflows

- Eliminate air bubbles, creasing and calliper variations

- Handles all sleeves with care

- Increase speed and quality to press

- Sleeve width: up 1000 / 1500 / 1800 / 2200 mm

- Printing repeats: 260mm > 1250mm (10,25” > 49”)

- Tape width: Up to 1420mm (56”)

- Sleeve adjustable hydraulic supports

Download: Camis SLEEVE MASTER AUTO and DEMOUNTER DMTS - Adobe PDF, 470KB

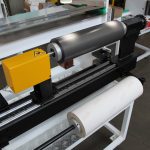

DEMOUNTER DMTS TWIN

CAMIS DMTS TWIN removes plates & tape simultaneously from 2 narrow web sleeves, drastically reducing time and also damages and fatigue associated with manually removing plates and tape at the end of a lengthy plate run. Specifically designed for sleeve presses, the DMTS TWIN uses the original and hugely effective powered tape applicator, the TAPER SLIDE, to remove the manual tape application issues to ensure that all types of tape are mounted perfectly on all sleeves.

- Reduce Damage to plates

- Reduce operator fatigue

- Increases the productivity of the plate mounters, removing the plate removal and tape operation from their workflows

- Eliminate air bubbles, creasing and calliper variations

- Handles all sleeves with care

- Increase speed and quality to press

- Sleeve width: up to 2 x 680mm (2x 26,8“)

- Printing repeats: 260mm > 1250mm (10,25” > 49”)

- Tape width: Up to 700mm (27,5”)

- Sleeve adjustable hydraulic supports

Download: Camis Plate Mounting Solutions - Adobe PDF, 1.5MB

Downloads

Camis Plate Mounting Solutions - Adobe PDF, 1.5MB

Camis SLEEVE MASTER AUTO and DEMOUNTER DMTS - Adobe PDF, 470KB

Camis DM Demounter - Adobe PDF, 2.3MB

Camis IRISMALL Mounter - Adobe PDF, 2.3MB