About Twen

Twen was created with a clear objective in mind: “Eliminate ink transfer as a variable in the printing process.” Their team has more than 25 years of experience in the flexographic industry and has worked over the years with the major anilox manufacturers in the market. This has enabled them to deeply understand how anilox are manufactured and closely analyze their performance to gain the required vision and "Know-how" to tackle complex problems with real solutions. The result is anilox laser cleaning solutions that tick all the boxes: Safe, efficient, profitable, and environmentally friendly.

TWEN has developed a laser cleaning solution that eliminates any ink residues deposited in the anilox cells safely and efficiently thanks to their advanced laser technology and intuitive machine configuration. Their laser cleaners will ensure that consistency in print quality is achieved every time while reducing press downtime for color matching and dramatically improving productivity.

TWEN TAC_M - Multi Station Anilox Laser Cleaning Solution

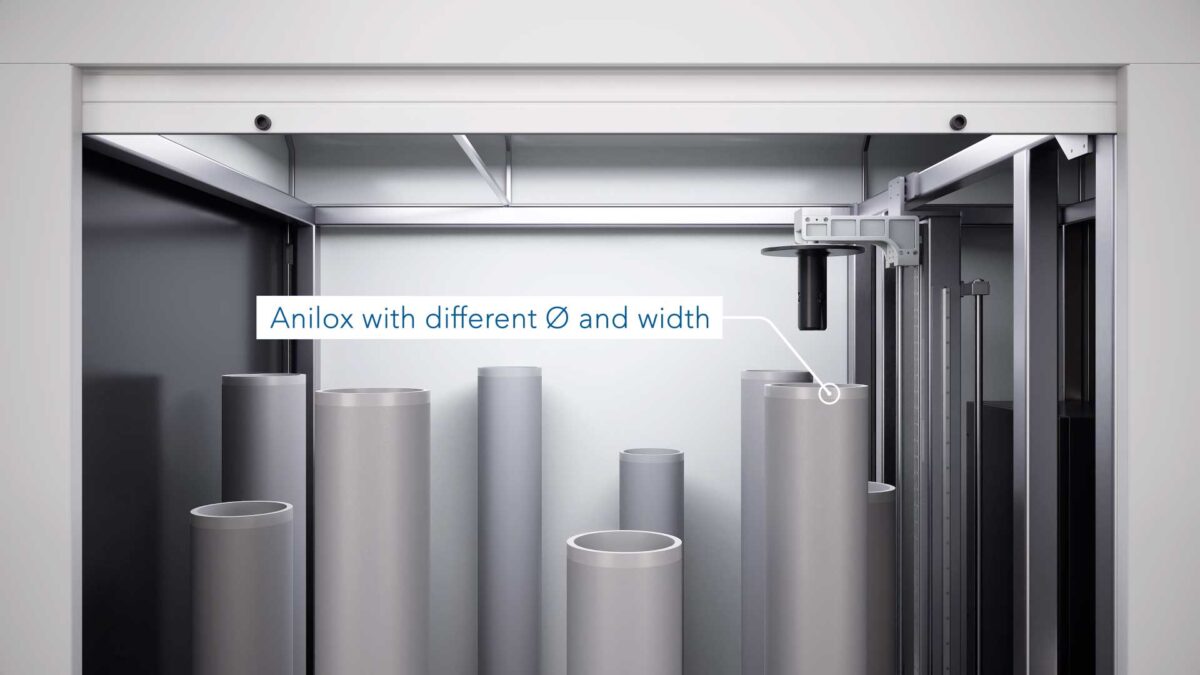

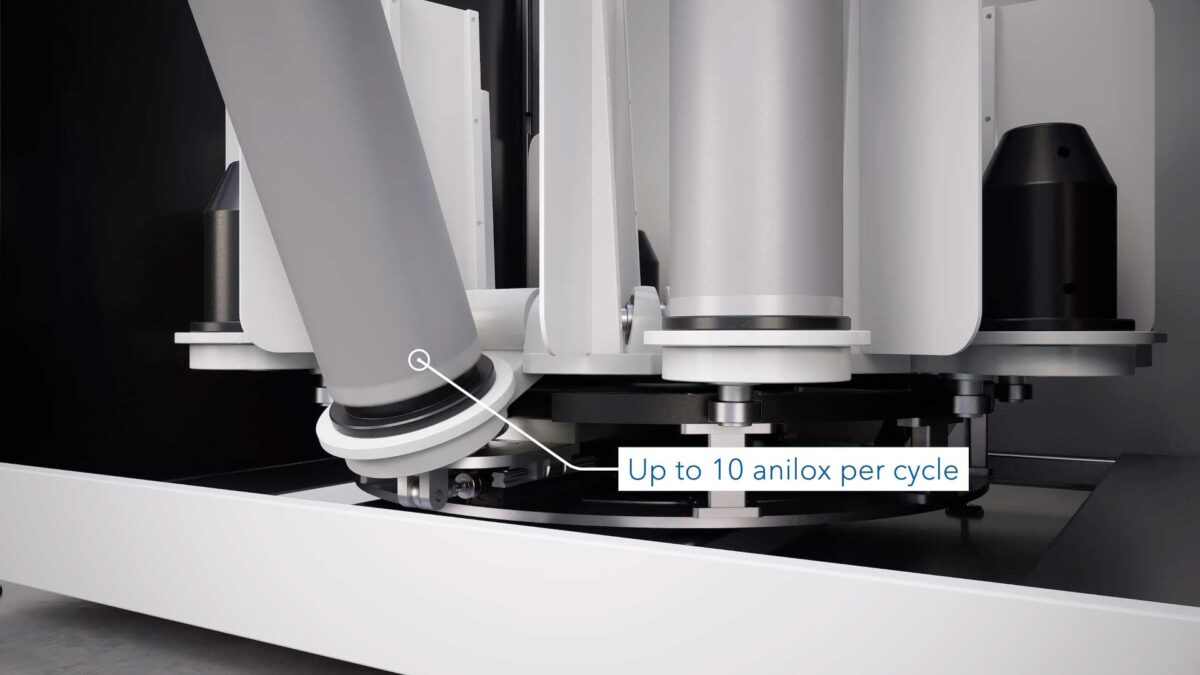

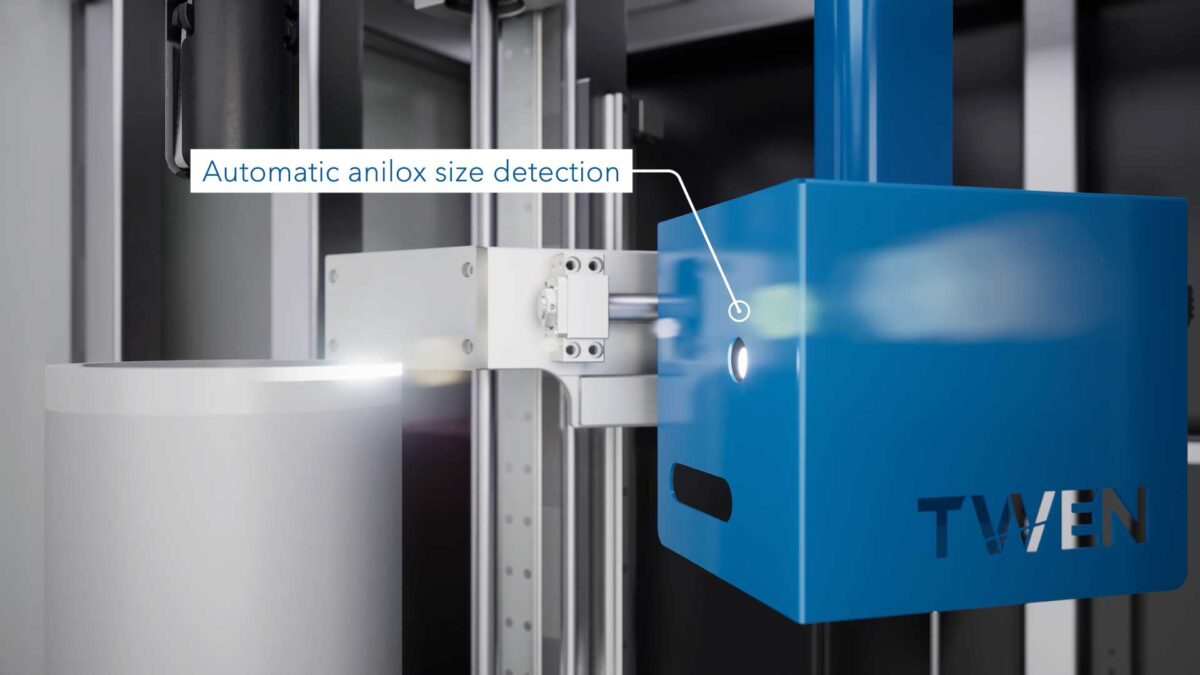

The TWEN TAC_M is a laser cleaner for cleaning multiple anilox sleeves, with a 10 anilox capacity. The sleeves can be of different dimensions. The unit automatically senses the anilox length and diameter for higher utilization. The unit has autofocus laser technology and a direct drive motion laser head for its laser-based Touch & Clean® system.

The TAC_M uses a low-power high-speed scanner fiber laser for harmless cleaning that has been externally audited by an anilox manufacturer. The laser source has a long life span that requires very low maintenance.

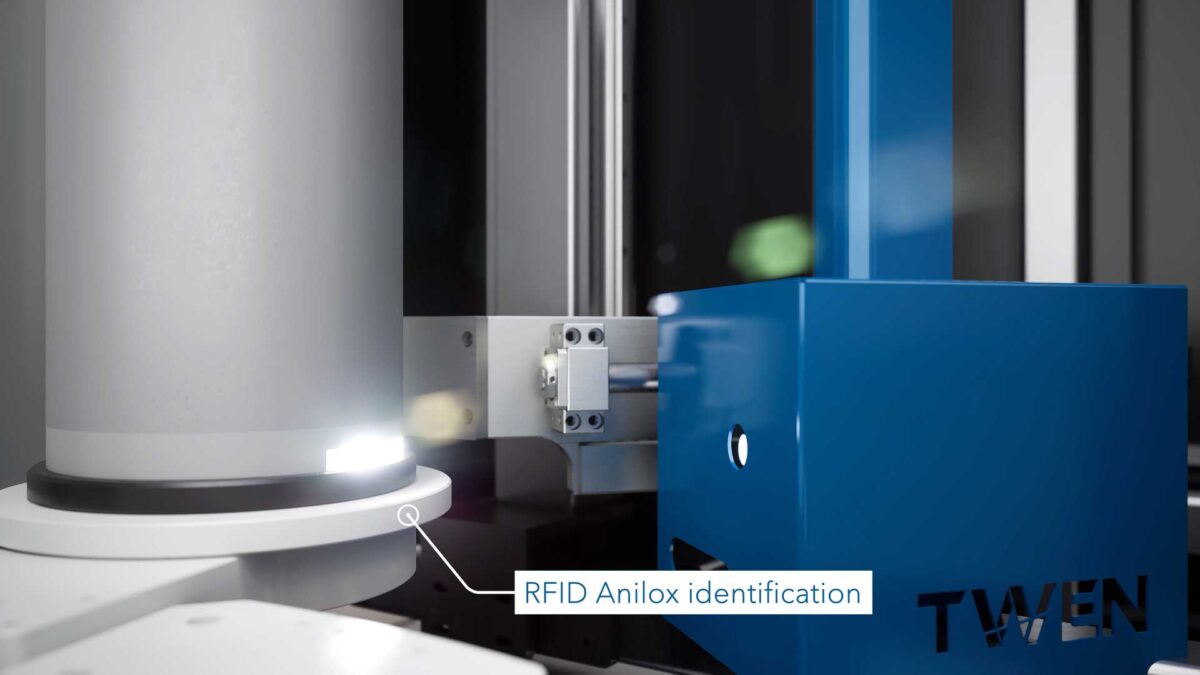

The unit features Siemens components with safety redundancies that guarantee a harmless operation for the ceramic and the operator. It is operated with a touch panel interface that collects data from each cleaning, which ensures full traceability of the process. Additionally, an RFID option allows users to track individual anilox automatically which eliminates potential human error.

The Loading System is a multi-anilox platform that can handle up to 10 anilox at one time, with different diameters that cover the full mid- and wide-web press sizes. The Rotation system consists of a maintenance-free table with direct drive.

The Laser Head features servo-driven laser displacement with the highest accuracy, thanks to its design inspired by CI flexo presses. Such accurate design allows smooth laser head displacement, which together with the automatic size detection makes this equipment the safest in the market.

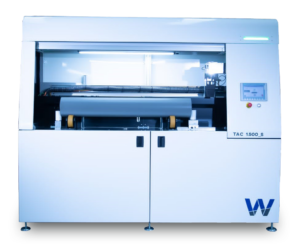

TWEN TAC_S - Laser Anilox Cleaning Solution

The TWEN TAC_S is a laser cleaner for sleeved and solid anilox. TAC_S uses autofocus laser technology and a direct drive motion for its laser-based Touch & Clean® system.

A low-power fiber laser is externally audited to provide safe by an anilox manufacturer, harmless cleaning with very low maintenance. Easy to use with zero damage to the anilox. No consumables are required, and there are no maintenance or operating costs. The operating cost can be as low as $1 per cleaned anilox.

The TWEN TAC_S features Siemens components with safety redundancies that guarantee a harmless operation for the ceramic and the operator. It is operated with a touch panel interface that collects data from each cleaning, which ensures full traceability of the process. Additionally, an RFID option allows users to track individual anilox automatically which eliminates potential human error.

TAC_S Machine Model

Standardization is key in today's industry, and for that reason, we build one model that covers the mid- and wide-web CI press sizes, leading to a much more effective service and spare parts availability.

• TAC-1.700 S Anilox laser cleaning solution for anilox up to 1700mm length (67 inches)

• Custom-made sizes are also available to fit the client ́s needs

For more information on TWEN Laser Anilox Cleaners, or to learn more about other excellent time-saving solutions, you can e-mail us here, or call us at: 800-445-4017.