Crystal Technology Combines Flexo Plate Imaging and Exposure

Esko Crystal technology, newly introduced at Drupa, allows flexo printers to combine plate imaging and exposure. This means compressing a complex process into a single operation that cuts manual handling steps in half. The key to this productivity gain is connecting two newly introduced devices: the XPS Crystal 5080 and the CDI Crystal 5080.

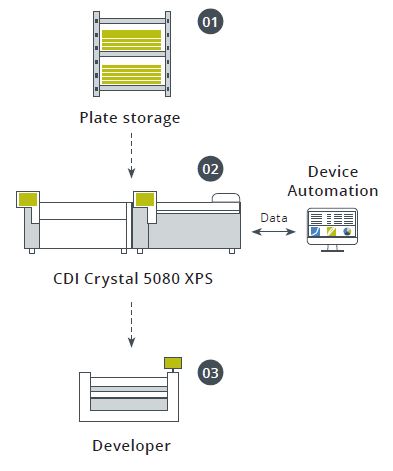

The XPS Crystal 5080, Esko's new flexo plate UV LED exposure device, combines UV main and back exposure into a single operation. This device can be connected seamlessly to the CDI Crystal 5080 -- Esko's new digital flexo plate imager (based on current industry leading CDI technology). Together, these form a single device -- the CDI Crystal 5080 XPS -- which combines plate imaging and exposing into a single operation. The combined solution cuts the number of manual handling steps by 50% compared to other technologies and reduces the time needed to produce a press-ready plate by almost 70%.

...And Puts Prepress in the Driver's Seat

Once these operations are combined through the CDI Crystal 5080 XPS, Esko's Device Manager puts the prepress department in the drivers seat, providing all the necessary information to prioritize and organize plate making queues to produce the right plate at the right time. With Device Manager, the work in progress, status and the queues of all connected devices are clearly visualized on screen.

- Reducing complexity in the plate making room

- Making production planning transparent and controlled

- Simplifying reporting and analytics

Next Generation Plate Room

Benefits

- Reduce manual steps by 50%

- Reduce errors by 50% – less plate waste

- Reduce operator time by 73%

The CDI Crystal 5080 simplifies flexo imaging

In today’s market, rushing jobs at the last minute at high quality has become the norm.

Traditional multi-step flexo plate making processes hinder productivity, cause errors and rework, and reduce press uptime. In the end, that harms the profitability of your operation.

A better way to produce flexo plates

The Esko CDI Crystal 5080 provides the foundation for an impressive reduction of complexity in the plate room. This lays the groundwork for full integration and automation of plate imaging and UV exposure.

The XPS Crystal 5080 improves consistency with patented UV LED exposure

Plate consistency is one of the keys to achieve and maintain optimal print quality. One of the main factors influencing plate stability is the plate’s UV exposure.

The innovative XPS Crystal 5080 optimally combines UV main and back exposure. Unlike UV frames using light bulbs fluctuating in output the XPS Crystal uses UV LEDs which don’t need warmup time and always emit consistent radiation.

A synchronised and optimally controlled UV main and back exposure produces highly consistent digital flexo plates – for every digital flexo plate type at every time of your production day.