Esko HD Flexo is the next step in high quality flexo printing.

HD Flexo is a new process for making digital flexographic (flexo) plates. The improved plates are higher quality and print more consistently than standard digital flexo plates. Esko HD Flexo may be implemented without scrapping existing equipment and working methods.

FINALLY A VALID ALTERNATIVE FOR OFFSET AND GRAVURE

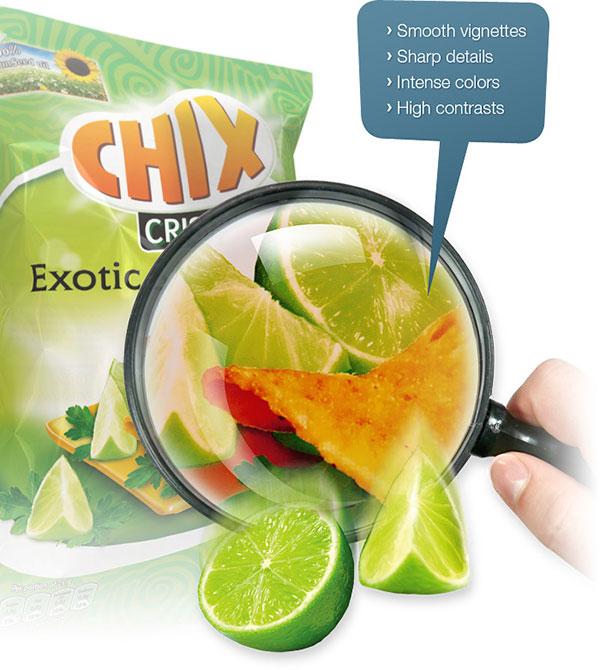

The quality of offset and gravure printing has always been somewhat of a Holy Grail for flexo. But, with HD Flexo, the gap is closed. Bringing consistency, vibrant colors and increased print quality, HD Flexo raises the industry standard in flexo printing.

Flexo printing can now compete with offset for quality labels and with gravure printing for flexible packaging. In addition, digital plate exposure ensures greater consistency in plate production and in printing.

EXCEPTIONAL FLEXO PRINTING PLATES

Exceptional flexo results start with exceptional flexo printing plates. With Esko's HD Flexo, not only are you able to deliver a new level of flexo quality. You can also reduce the makeready time on the press. and what's more, HD Flexo printing plates deliver greater run lengths. And because they need fewer washing cycles, the press is optimally used.

There is a sustainable benefit as well. Printing flexible packaging on a flexo press instead of gravure reduces energy use and CO2 emissions by as much as 50%. Converters and brand owners can improve sustainability by taking advantage of the higher quality offered by HD Flexo.

THE FULL HD FLEXO DIFFERENCE

Full HD Flexo is a new process for making digital flexographic (flexo) plates. The improved plates are higher quality and print more consistently than standard digital flexo plates. Full HD Flexo may be implemented without scrapping existing equipment and working methods.

Full HD Flexo includes a technique called "in-line-UV". In Esko's imaging device this is done with an LED beam built into the machine -- completely eliminating a manual step. This improves consistency of the main exposure because the LED lights inside the CDI do not deteriorate like the UV bulbs in a lightbox (which often suffer from instable and changing light intensity.) Everything in the imaging workflow is completely controlled. By aligning light intensity and imaging speed the CDI can digitally create both round-top and flat-top dots in a fully-digitally-controlled environment. With digital control of the dots comes a top-quality flexo printing plate with superb solid ink laydown, sharp details and gradients that fade to zero.

Want to know more?

Download - the white paper

Download - the brochure